3aa batteries make one d-cell 3D for print

1949 Views 2 Likes 0 Downloads Download the piece here from 3dforprint

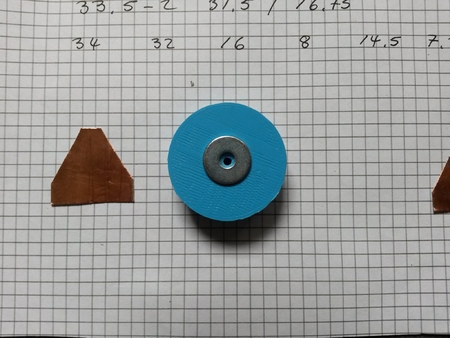

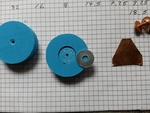

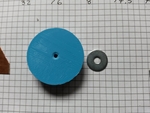

This is the developmen...t of the part. The first prototype with minimal material usage, but also showing, that the bottom layer must be thicker when some machining is done. for the time being the prototype and the images for some of the part.

I will definitely make it somewhat shorter than a D-Cell (61.5 mm) as the spring in these compartments for D-Cells are usually very long.

D-Cell: 61.5 mm long, 34.2 mm diameter (some sources say 33.2)

AA-Cell 50.5 mm long, 14.5 mm diameter (I have not found any in my huge collection of NiMh cells that exceeps 14.2 mm, so I dimension towards 14.5 mm)

As it looks right now there will be a (+) and a (-) part of the battery pack, maybe I still manage to make it universal.

Created the PT2, but even with support it does not print as I want it, as the recessed part at the bottom is not printed with support (I have no clue why...)

The design I have drastically updated and will publish hopefully soon. However there is one important issue that might make this totally useless. considering 3 cells in parallel and not all of them having absolutely identical voltage makes current flow between the cells, which could lead to very fast discharge, especially when high power low internal resistance cells are used, e.g. like NiMh. I will do some measurements with my cells when time is available

finally continued:

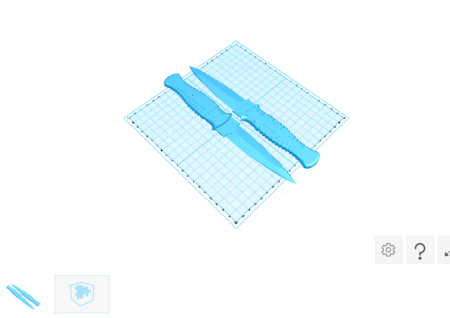

PT5 parts

top and bottom part are identical and middle section using less material. Probably wall thickness could be further reduced. Parts do not need to be kept together, the spring in the D-cell compartment will do the job. Worked fine with the copper tape and copper screws this summer for bbq (I would assume one A cell would have done the job as well ;-)). The circles at the bottom and top part need to be machined out, so the screw can be properly placed. Will add some images when all is assembled, but maybe you already get the point.

I also measured the current flow between unevenly charged cells and it is considerable, especially when no load is applied and current does not 'know' where to go, so do not leave it in the D-cell compartment, the cells will be discharged rather fast. Use cells ideally bought together, as they 'might' have very similar characteristics, so self-discharge is minimal. One bad cell can easily ruin the other two cells within a few hours.

The higher the current drawn form the pack, the lower the self discharge due to 'unwanted' balancing between the cells. With ideal cells, this would all work perfect.

Disclaimer: use at your own risk

a sunday aft...ernoon

some PLA, some screws (ideally copper) some self-adhesive copper tape,

The original idea from pavel.karoukin (Thanks)

Designer

kuno3d model description

Inspired by pavel.karoukin's battery back for a D-Cell I started to make my own drawings, making it all a little bit differentThis is the developmen...t of the part. The first prototype with minimal material usage, but also showing, that the bottom layer must be thicker when some machining is done. for the time being the prototype and the images for some of the part.

I will definitely make it somewhat shorter than a D-Cell (61.5 mm) as the spring in these compartments for D-Cells are usually very long.

D-Cell: 61.5 mm long, 34.2 mm diameter (some sources say 33.2)

AA-Cell 50.5 mm long, 14.5 mm diameter (I have not found any in my huge collection of NiMh cells that exceeps 14.2 mm, so I dimension towards 14.5 mm)

As it looks right now there will be a (+) and a (-) part of the battery pack, maybe I still manage to make it universal.

Created the PT2, but even with support it does not print as I want it, as the recessed part at the bottom is not printed with support (I have no clue why...)

The design I have drastically updated and will publish hopefully soon. However there is one important issue that might make this totally useless. considering 3 cells in parallel and not all of them having absolutely identical voltage makes current flow between the cells, which could lead to very fast discharge, especially when high power low internal resistance cells are used, e.g. like NiMh. I will do some measurements with my cells when time is available

finally continued:

PT5 parts

top and bottom part are identical and middle section using less material. Probably wall thickness could be further reduced. Parts do not need to be kept together, the spring in the D-cell compartment will do the job. Worked fine with the copper tape and copper screws this summer for bbq (I would assume one A cell would have done the job as well ;-)). The circles at the bottom and top part need to be machined out, so the screw can be properly placed. Will add some images when all is assembled, but maybe you already get the point.

I also measured the current flow between unevenly charged cells and it is considerable, especially when no load is applied and current does not 'know' where to go, so do not leave it in the D-cell compartment, the cells will be discharged rather fast. Use cells ideally bought together, as they 'might' have very similar characteristics, so self-discharge is minimal. One bad cell can easily ruin the other two cells within a few hours.

The higher the current drawn form the pack, the lower the self discharge due to 'unwanted' balancing between the cells. With ideal cells, this would all work perfect.

Disclaimer: use at your own risk

3d model print parameters

a new gadget for the bbq (Kettle Rotisserie) which has a 220V Motor. An alternative battery driven motor from Landi (Swiss 'farm' store)a sunday aft...ernoon

some PLA, some screws (ideally copper) some self-adhesive copper tape,

The original idea from pavel.karoukin (Thanks)