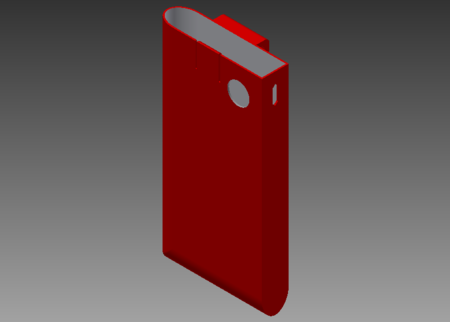

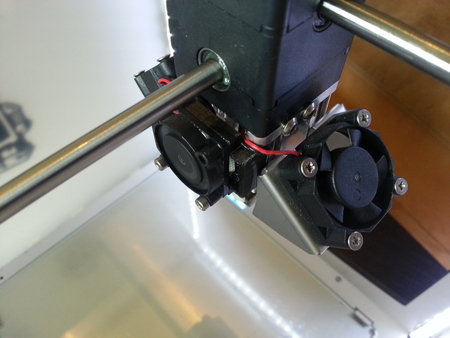

Neotko fatiroberti bondtech feeder for um2+ / um3 3D for print

9560 Views 2 Likes 0 Downloads Download the piece here from 3dforprint

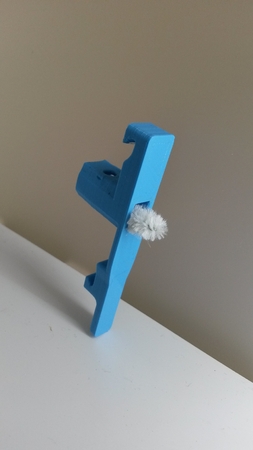

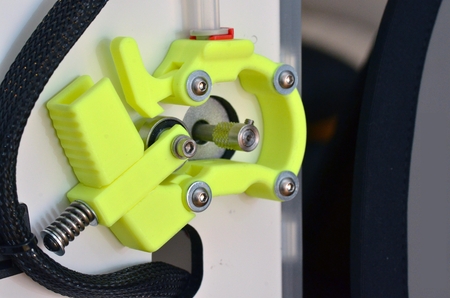

You will need to down...load the LATCH from the IRobertI original design

https://www.youmagine.com/designs/alternative-um2-feeder-version-two

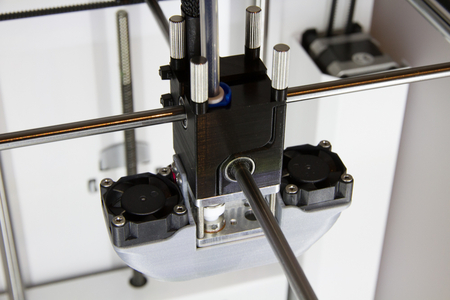

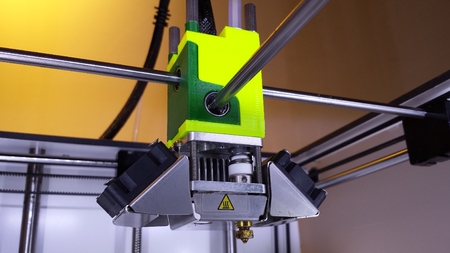

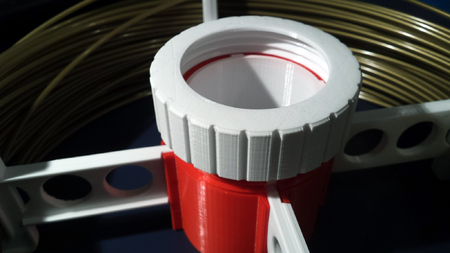

Basically I wanted to have dual Bondtech drivegears on my UM3. But buying two full kits is around 300€, by doing this design I could use the 40€ drive gears Bondtech sells and change my 2 feeders reusing the Geared Extruder system from the UM3.

Downside? To avoid the feeder from hitting the spool, you need to reverse the motors direction. Easiest way is by changing the First two colores cables from 1234 to 2134. If you don't know how to do this, this isn't your feeder ;)

If you don't want to reverse the motor you might need to use a different spool system and print all mirror.

Use supports for anything 50degrees or more. Also use 50% or so support density, or the nut holes will print badly. Same goes for the feeder arm, and areas that do need support. I didn't design my supports just because I didn't saw it necessary. Used default S3D support settings with 50% support density and all worked perfectly and was very easy to remove them.

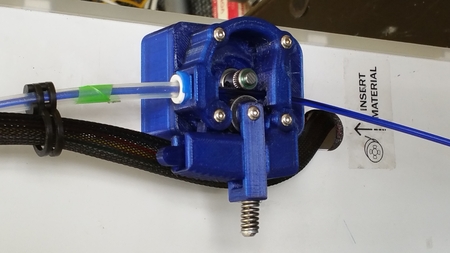

The inside area between the part a-b should hold a small peace of bowden tube. If you can't do that, it might be problematic to feed the filament since is designed this way for many reasons.

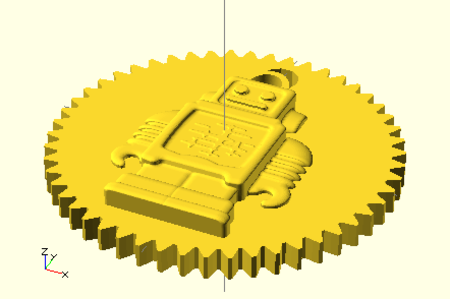

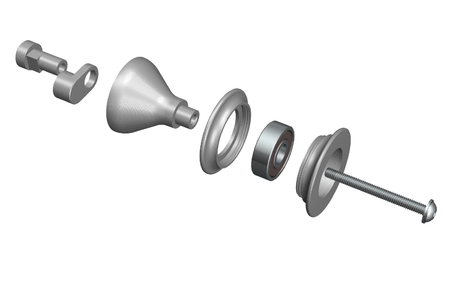

The Printable-Shaft-Adapter MUST be printed at 80-90 infill 2-3 perimeters and I used -0.03 horizontal expansion to print this part (not the feeder). This part is the adapter that holds the bondtech drivegear and it uses a m3 30mm inside, you will notice that the screw passes soft until the end, that part need's to be screw in, don't force it, is made to fit perfectly. If something fails, your filament size might not be correct, check it with a caliper.

To print the Feeder use 0.18 or less, but it doesn't need more resolution. 0.2 is possible but I don't like how the part where the filament passes looks. 0.18 was perfect on all the test prints while making this.

To print the second Core extruder mirror all the parts.

There are 3 Versions.

1.75mm using 6mm-4mm bowden

1.75mm using 4mm-2mm bowden

2.85mm using 6-3mm classic UM bowden

To use this feeder you need a Bondtech Drive gears and a 4mm Shaft 22mm long (bondtech sells them too).

This Feeder could be really really fast adapted to use MK8, but would need a change on the IRobertI Arm to fit the UM2+/UM3 feeder bearing.

I did use a spring that bondtech did sell before that isn't included now. If they don't sell it to you (asking never hurts) you can reuse the UM2+/um3 spring, but mind that you will need a M3 35-40mm to use it. Also the force of the spring is quite too much from what is necessary for bondtech gears, so.. mind the force.

One spring for the IRobertI Arm. You can reuse the strong spring of the um2+/um3 but I think is way too much force for what is ne...cessary. Remember this isn't a brute force feeder, bondtech gears do push the filament very precisely. So just pushing hard with the spring doesn't help feeding with quality.

- Some x2 M3 10-12-14mm depends if you use it on um3 (you can reuse his small m3) or on a um2+

Designer

Neotko / Sugarpop!3d model description

Reusing the UM2+ / UM3 Feeder to use the Cheap Drivegears DIY kit from Bondtech while keeping the motor, gears and some screws.You will need to down...load the LATCH from the IRobertI original design

https://www.youmagine.com/designs/alternative-um2-feeder-version-two

Basically I wanted to have dual Bondtech drivegears on my UM3. But buying two full kits is around 300€, by doing this design I could use the 40€ drive gears Bondtech sells and change my 2 feeders reusing the Geared Extruder system from the UM3.

Downside? To avoid the feeder from hitting the spool, you need to reverse the motors direction. Easiest way is by changing the First two colores cables from 1234 to 2134. If you don't know how to do this, this isn't your feeder ;)

If you don't want to reverse the motor you might need to use a different spool system and print all mirror.

Use supports for anything 50degrees or more. Also use 50% or so support density, or the nut holes will print badly. Same goes for the feeder arm, and areas that do need support. I didn't design my supports just because I didn't saw it necessary. Used default S3D support settings with 50% support density and all worked perfectly and was very easy to remove them.

The inside area between the part a-b should hold a small peace of bowden tube. If you can't do that, it might be problematic to feed the filament since is designed this way for many reasons.

The Printable-Shaft-Adapter MUST be printed at 80-90 infill 2-3 perimeters and I used -0.03 horizontal expansion to print this part (not the feeder). This part is the adapter that holds the bondtech drivegear and it uses a m3 30mm inside, you will notice that the screw passes soft until the end, that part need's to be screw in, don't force it, is made to fit perfectly. If something fails, your filament size might not be correct, check it with a caliper.

To print the Feeder use 0.18 or less, but it doesn't need more resolution. 0.2 is possible but I don't like how the part where the filament passes looks. 0.18 was perfect on all the test prints while making this.

To print the second Core extruder mirror all the parts.

There are 3 Versions.

1.75mm using 6mm-4mm bowden

1.75mm using 4mm-2mm bowden

2.85mm using 6-3mm classic UM bowden

To use this feeder you need a Bondtech Drive gears and a 4mm Shaft 22mm long (bondtech sells them too).

This Feeder could be really really fast adapted to use MK8, but would need a change on the IRobertI Arm to fit the UM2+/UM3 feeder bearing.

I did use a spring that bondtech did sell before that isn't included now. If they don't sell it to you (asking never hurts) you can reuse the UM2+/um3 spring, but mind that you will need a M3 35-40mm to use it. Also the force of the spring is quite too much from what is necessary for bondtech gears, so.. mind the force.

3d model print parameters

- At least x4 m3 30One spring for the IRobertI Arm. You can reuse the strong spring of the um2+/um3 but I think is way too much force for what is ne...cessary. Remember this isn't a brute force feeder, bondtech gears do push the filament very precisely. So just pushing hard with the spring doesn't help feeding with quality.

- Some x2 M3 10-12-14mm depends if you use it on um3 (you can reuse his small m3) or on a um2+