Planetary gearbox extruder 3D for print

6022 Views 1 Likes 0 Downloads Download the piece here from 3dforprint

There were mistakes in the cover and base, which crept in at the last minute - I've fi...xed them, and posted those parts as their own files.

I've tested this extruder over 2 days of fairly continuous printing with little sign of wear.

OpenSCAD sources available on GitHub - https://github.com/Lodran/planetary-gearbox-extruder

Print the parts with PLA, or another wear resistant plastic. If you're worried about heat, print the gearbox parts with PLA, and the other parts with ABS.

Using a small screwdriver, break the support structures from inside the nut and bolt head pockets.

Insert M3 nylock nuts into all of the nut pockets. I find that using a bolt to align them before pushing them into place usually works well - if not, then I use the bolt to pull them into place.

Remove the support structure that blocks the bolt head recess in the upper planet carrier (either drill it with an M5 drillbit, or just cut it out with a hobby knife).

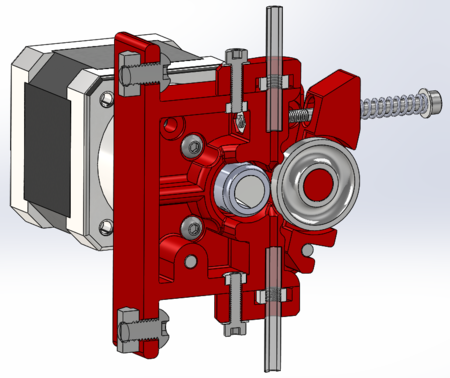

Insert the M5 bolt into the upper planet carrier. If necessary, use the drive wheel and a nut to pull the bolt into place (then remove the drive wheel and nut).

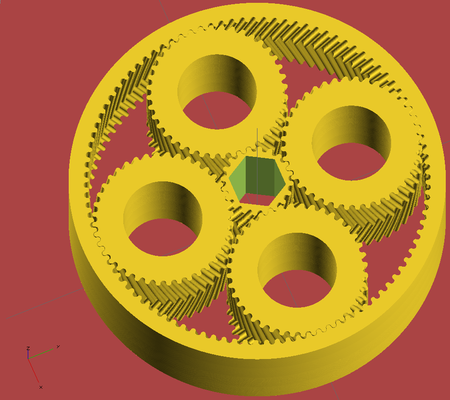

Assemble the rest of the planet carrier, along with its gears, using 3 M3x6 bolts. There is an alignment notch on the side of the carrier to assist with assembly.

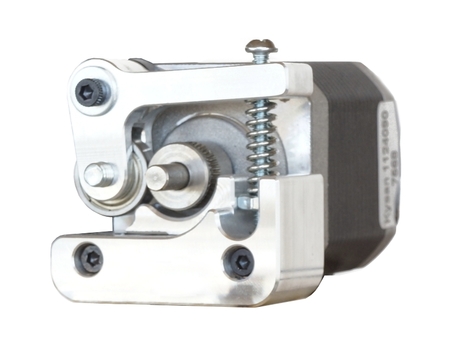

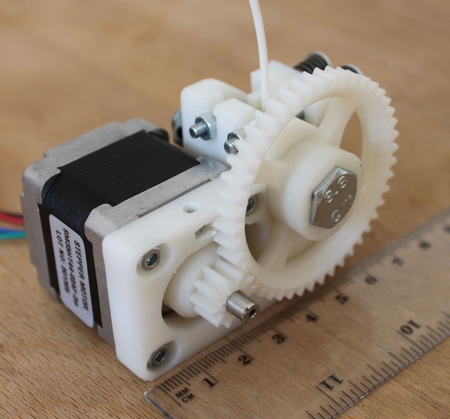

Attach the sun gear to the motor. Use threadlock to secure the screw.

Attach the base to the motor using 4 M3x10 bolts.

Insert one of the 105 bearings into the cover, run the drive bolt through the cover, and fix it in place using the drive wheel. Use threadlock to secure the screw. Be certain to leave a small gap between the cover and wheel so that the planet carrier rotates freely.

Align the ring gear to the planet gears, and position it against the cover.

Align the planet gears to the sun gear, and position the ring gear against the base. Attach the cover to the base using 4 M3x25 bolts.

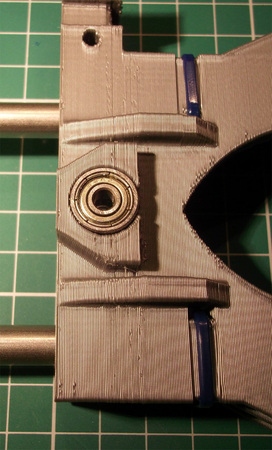

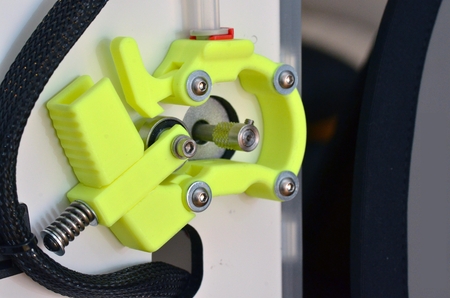

Insert the 623 bearing into the pinch wheel bracket, and attach it with an M3x16 bolt.

Insert the other 105 bearing into the extruder frame.

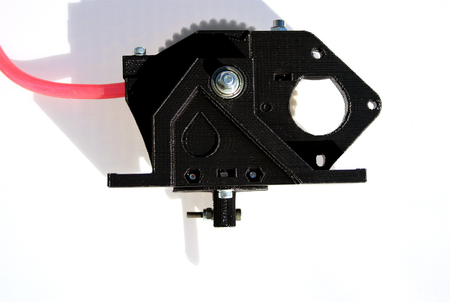

Align the extruder frame and pinch wheel bracket with the cover, and attach it using 3 M3x16 bolts.

Fix the drive bolt in position using the M5 nylock nut - be sure to leave it loose enough to allow things to rotate smoothly. (I've found that after breaking the gearbox in, I have to insert an allen wrench into the drive wheel's set screw to prevent the gears from rotating while I tighten the M5 nylock nut.)

You'll notice that I haven't told you when (or where) to grease it. That's because I run it for an hour or so to make sure everything is broken in before I grease it.

Break it in, tear it down, grease the insides of the planet gears, and all gear teeth, then reassemble.

- 2x 105 Bearing - [Source: HobbyKing](http://www.hobbyking.com/hobbyking/store/__21549__Ball_Bearing_5x10x4mm..._2pcs_bag_Turnigy_Trailblazer_1_8_XB_and_XT_1_5_.html)

- 1x 623 Bearing - [Source: HobbyKing](http://www.hobbyking.com/hobbyking/store/__11726__HK600GT_Ball_Bearings_Pack_3x10x4mm_4pcs_bag.html)

- 1x 10T/5MM M1 Pinion - [Source: HobbyKing](http://www.hobbyking.com/hobbyking/store/__45522__10T_5mm_M1_Hardened_Steel_Pinion_Gear_1pc_.html)

- 1x 5mm x 12mm x 11mm Drive wheel - [Source: Reprap Discount](http://www.reprapdiscount.com/mechanics/52-hobbed-pulley.html#/bore_length_diameter_hob_diameter-5mm_11mm_12mm_10_1mm)

- 15x M3 Nylock nut

- 3x M3x6 bolt

- 4x M3x10 bolt

- 3x M3x16 bolt

- 3x M3x20 bolt

- 6x M3x25 bolt

- 2x M3 washer

- 1x M5 Nylock nut

- 1x M5x30 bolt

- Threadlock

- Grease

Designer

Lodran3d model description

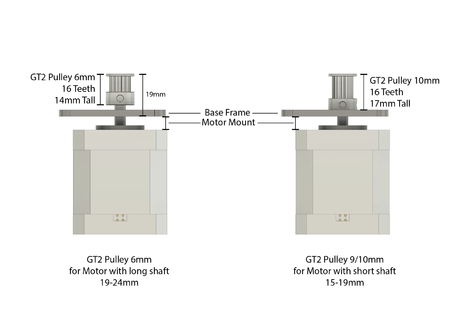

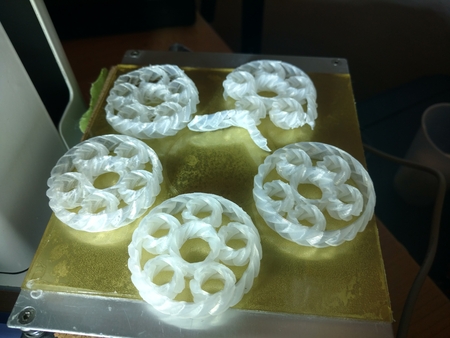

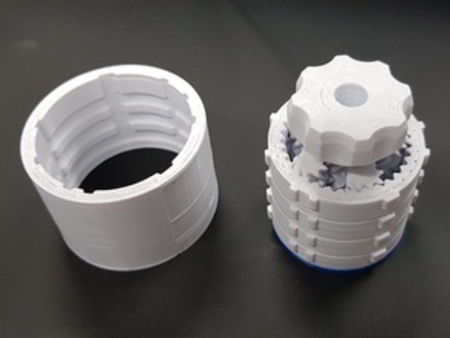

A compact extruder with an integrated 5.6:1 planetary gearbox.There were mistakes in the cover and base, which crept in at the last minute - I've fi...xed them, and posted those parts as their own files.

I've tested this extruder over 2 days of fairly continuous printing with little sign of wear.

OpenSCAD sources available on GitHub - https://github.com/Lodran/planetary-gearbox-extruder

Print the parts with PLA, or another wear resistant plastic. If you're worried about heat, print the gearbox parts with PLA, and the other parts with ABS.

Using a small screwdriver, break the support structures from inside the nut and bolt head pockets.

Insert M3 nylock nuts into all of the nut pockets. I find that using a bolt to align them before pushing them into place usually works well - if not, then I use the bolt to pull them into place.

Remove the support structure that blocks the bolt head recess in the upper planet carrier (either drill it with an M5 drillbit, or just cut it out with a hobby knife).

Insert the M5 bolt into the upper planet carrier. If necessary, use the drive wheel and a nut to pull the bolt into place (then remove the drive wheel and nut).

Assemble the rest of the planet carrier, along with its gears, using 3 M3x6 bolts. There is an alignment notch on the side of the carrier to assist with assembly.

Attach the sun gear to the motor. Use threadlock to secure the screw.

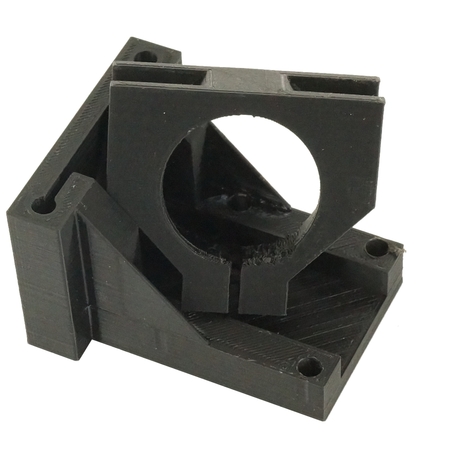

Attach the base to the motor using 4 M3x10 bolts.

Insert one of the 105 bearings into the cover, run the drive bolt through the cover, and fix it in place using the drive wheel. Use threadlock to secure the screw. Be certain to leave a small gap between the cover and wheel so that the planet carrier rotates freely.

Align the ring gear to the planet gears, and position it against the cover.

Align the planet gears to the sun gear, and position the ring gear against the base. Attach the cover to the base using 4 M3x25 bolts.

Insert the 623 bearing into the pinch wheel bracket, and attach it with an M3x16 bolt.

Insert the other 105 bearing into the extruder frame.

Align the extruder frame and pinch wheel bracket with the cover, and attach it using 3 M3x16 bolts.

Fix the drive bolt in position using the M5 nylock nut - be sure to leave it loose enough to allow things to rotate smoothly. (I've found that after breaking the gearbox in, I have to insert an allen wrench into the drive wheel's set screw to prevent the gears from rotating while I tighten the M5 nylock nut.)

You'll notice that I haven't told you when (or where) to grease it. That's because I run it for an hour or so to make sure everything is broken in before I grease it.

Break it in, tear it down, grease the insides of the planet gears, and all gear teeth, then reassemble.

3d model print parameters

- PLA or other wear resistant plastic.- 2x 105 Bearing - [Source: HobbyKing](http://www.hobbyking.com/hobbyking/store/__21549__Ball_Bearing_5x10x4mm..._2pcs_bag_Turnigy_Trailblazer_1_8_XB_and_XT_1_5_.html)

- 1x 623 Bearing - [Source: HobbyKing](http://www.hobbyking.com/hobbyking/store/__11726__HK600GT_Ball_Bearings_Pack_3x10x4mm_4pcs_bag.html)

- 1x 10T/5MM M1 Pinion - [Source: HobbyKing](http://www.hobbyking.com/hobbyking/store/__45522__10T_5mm_M1_Hardened_Steel_Pinion_Gear_1pc_.html)

- 1x 5mm x 12mm x 11mm Drive wheel - [Source: Reprap Discount](http://www.reprapdiscount.com/mechanics/52-hobbed-pulley.html#/bore_length_diameter_hob_diameter-5mm_11mm_12mm_10_1mm)

- 15x M3 Nylock nut

- 3x M3x6 bolt

- 4x M3x10 bolt

- 3x M3x16 bolt

- 3x M3x20 bolt

- 6x M3x25 bolt

- 2x M3 washer

- 1x M5 Nylock nut

- 1x M5x30 bolt

- Threadlock

- Grease

![[WIP] CerbrisReborn 1.75mm bowden extruder](https://www.3dforprint.com/modelos/4801/wip-cerbrisreborn-mm-bowden-extruder1_medium.jpg)