Ping pong popper 3D for print

911 Views 0 Likes 0 Downloads Download

"Ping Pong Popper" (named by our nieces, nephews and grandkids) is an easy to make 3D printed toy for the young ones (an...d some old ones) in our family, and they all love it!

Just two 3D printed parts, a spring, some string and a ping pong ball saves the grandparents / aunt / uncle (my wife and I) around $25.00 USD for a trip to the local indoor pizza parlor / arcade in an attempt to win one of these. And if we do win one, well, they're broken within an hour. Now I just print another (the green Ping Pong Popper is for my youngest grandson Gabe)!

As usual, I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to point them out as I do make mistakes in plenty.

Designed using Autodesk Fusion 360, sliced using Cura 3.5.1, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker 3 Extended.

Ping Pong Balls.

Springs (1 3/8" x 23/64" x .027" section or 35mm x 9.3mm x 7.mm section).

String

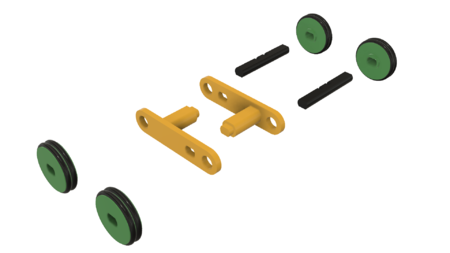

Parts I Printed.

One H...andle.stl.

One Spring Holder.stl.

I printed both parts at .15mm vertical resolution, 20% infill and no support.

Assembly.

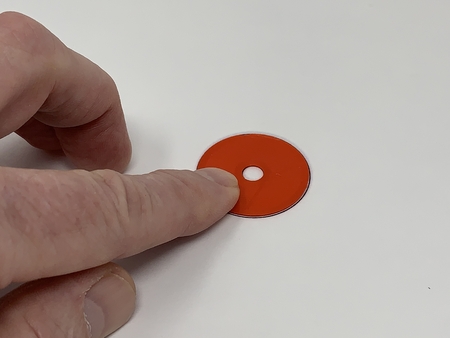

Using the small diameter end of "Spring Holder.stl" as a template, draw a circle on the ping pong ball surface.

Using a sharp modeling knife, cut out the inside portion of the circle (make sure to cut inside the pencil line). Alternatively to the draw and cut method, I used a 12mm step drill to cut the hole.

Test fit the spring holder in the hole. If the hole is too small, use a small round file to slightly enlarge it until the spring holder fits securely in the hole.

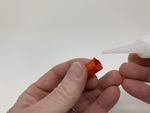

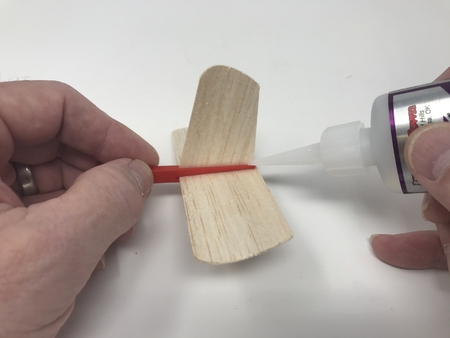

Insert the spring into the spring holder, then place small dots of thick cyanoacrylate (or hot melt) glue around the surface of the small end of the spring holder.

Slide the spring holder and spring into the ping pong ball and hold in place until the glue cures.

Tie one end a 3 foot length of string around the spring holder shoulder, and the remaining end in the hole in "Handle.stl" (I secured these knots with a small dot of thick cyanoacrylate glue).

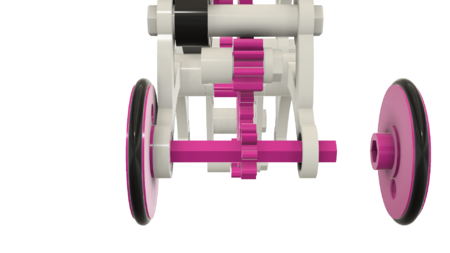

Press the ping pong ball assembly onto the handle as shown, then pop away!

And that's how I printed and assembled "Ping Pong Popper".

Hope you enjoy it!

Designer

Greg Zumwalt3d model description

A ping pong ball popper."Ping Pong Popper" (named by our nieces, nephews and grandkids) is an easy to make 3D printed toy for the young ones (an...d some old ones) in our family, and they all love it!

Just two 3D printed parts, a spring, some string and a ping pong ball saves the grandparents / aunt / uncle (my wife and I) around $25.00 USD for a trip to the local indoor pizza parlor / arcade in an attempt to win one of these. And if we do win one, well, they're broken within an hour. Now I just print another (the green Ping Pong Popper is for my youngest grandson Gabe)!

As usual, I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to point them out as I do make mistakes in plenty.

Designed using Autodesk Fusion 360, sliced using Cura 3.5.1, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker 3 Extended.

3d model print parameters

Parts I purchased.Ping Pong Balls.

Springs (1 3/8" x 23/64" x .027" section or 35mm x 9.3mm x 7.mm section).

String

Parts I Printed.

One H...andle.stl.

One Spring Holder.stl.

I printed both parts at .15mm vertical resolution, 20% infill and no support.

Assembly.

Using the small diameter end of "Spring Holder.stl" as a template, draw a circle on the ping pong ball surface.

Using a sharp modeling knife, cut out the inside portion of the circle (make sure to cut inside the pencil line). Alternatively to the draw and cut method, I used a 12mm step drill to cut the hole.

Test fit the spring holder in the hole. If the hole is too small, use a small round file to slightly enlarge it until the spring holder fits securely in the hole.

Insert the spring into the spring holder, then place small dots of thick cyanoacrylate (or hot melt) glue around the surface of the small end of the spring holder.

Slide the spring holder and spring into the ping pong ball and hold in place until the glue cures.

Tie one end a 3 foot length of string around the spring holder shoulder, and the remaining end in the hole in "Handle.stl" (I secured these knots with a small dot of thick cyanoacrylate glue).

Press the ping pong ball assembly onto the handle as shown, then pop away!

And that's how I printed and assembled "Ping Pong Popper".

Hope you enjoy it!