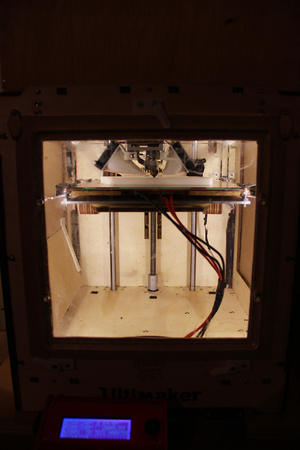

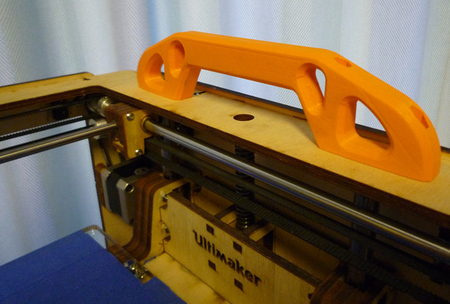

Aluminium-frame for the ultimaker 3D for print

800 Views 0 Likes 0 Downloads Download

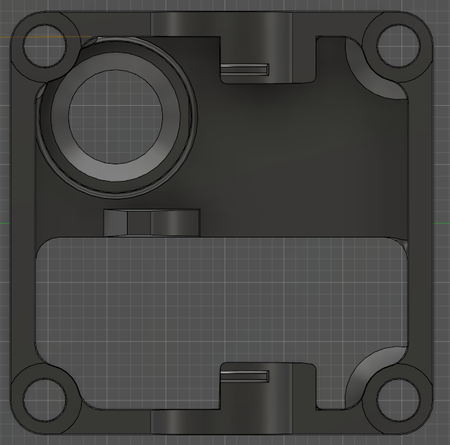

All the part files (except the plastic part) ...are in SolidEdge ST5 format. Just write a message to me if you or your lasercutter cannot read this file format.

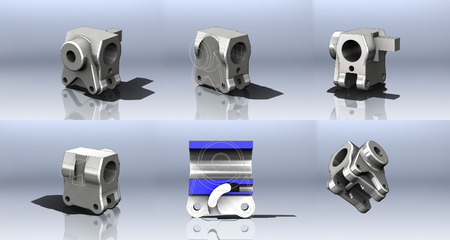

I made some additional changes to the Frame:

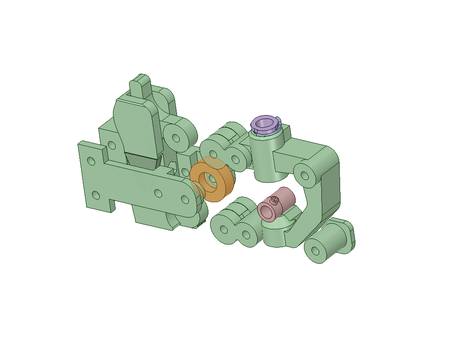

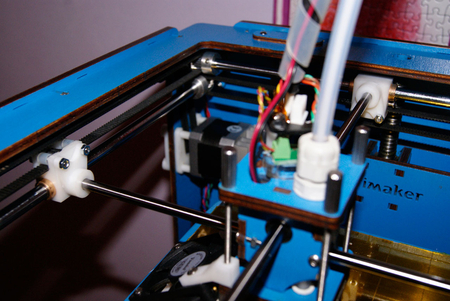

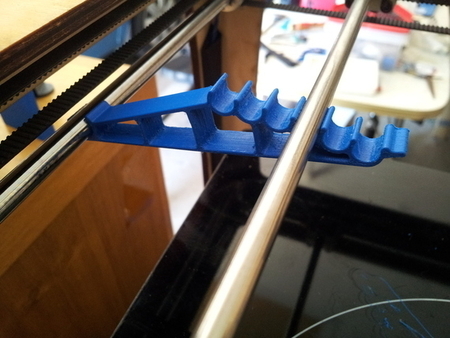

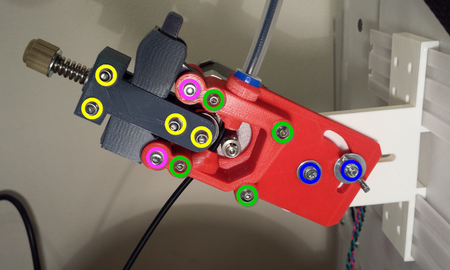

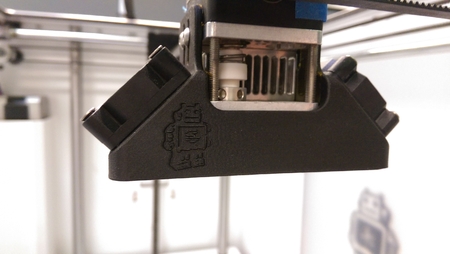

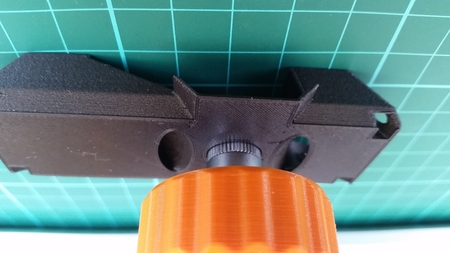

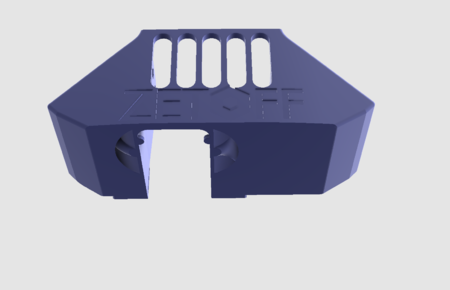

- Holders for a strong direct drive.

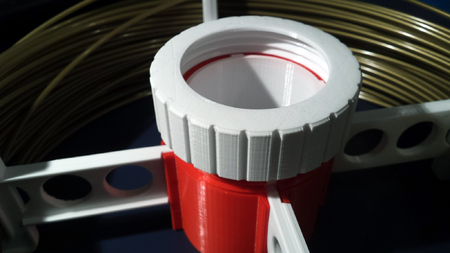

- Moving the spool-holder to take 3 kg-spools also in dual head mode.

- A deeper holder for the ultimaker-controller.

Advantages of this frame are:

- Less noise, no more rumbling of the wooden housing, especialli when infilling small parts.

- A perfect first layer. No more brighter and darker areas on it, because of more precise axles.

- No more temperature and humidity issues

- Perfect edges because of less backlash due to the direct drive

I took the 3D-Model from Thingiverse, changed the size of the mounting-noses and holes on the wooden parts to fit on aluminium parts. So this should not be made of wood, otherwise you will have too much space between the parts, and they will not clamp together.

The Holes for the bearings and the vertical axes i made 0,2 mm smaller for further treatment.

The parts can be made by lasercutting. The holes are too small to be lasercut. So they may be marked and drilled by hand to 3,4 mm. After putting all the parts together you can sew it together at the poins wher you can see the mating-noses from the outside, or you can drill threads and use M3 screws like the original wooden housing.

For my machine, afer some sanding and cleaning the whole frame was sandblasted with glass-perls to have a nice looking housing.

Finally the holes for the bearings and the vertical axes need to be reamed by a hand reamer 12 H7 or 16 H7.

I used some Loctite 641 retaining compound to fix the bearings into the holes. It would be even better to ream the holes with a Reamer in 16 K7 or M7 and press the bearings in, but they're hard to get and quite expensive.

Designer

Joel Bayard3d model description

This is an aluminium Frame for the Ultimaker. It makes this great machine even more precise and faster.All the part files (except the plastic part) ...are in SolidEdge ST5 format. Just write a message to me if you or your lasercutter cannot read this file format.

I made some additional changes to the Frame:

- Holders for a strong direct drive.

- Moving the spool-holder to take 3 kg-spools also in dual head mode.

- A deeper holder for the ultimaker-controller.

Advantages of this frame are:

- Less noise, no more rumbling of the wooden housing, especialli when infilling small parts.

- A perfect first layer. No more brighter and darker areas on it, because of more precise axles.

- No more temperature and humidity issues

- Perfect edges because of less backlash due to the direct drive

I took the 3D-Model from Thingiverse, changed the size of the mounting-noses and holes on the wooden parts to fit on aluminium parts. So this should not be made of wood, otherwise you will have too much space between the parts, and they will not clamp together.

The Holes for the bearings and the vertical axes i made 0,2 mm smaller for further treatment.

The parts can be made by lasercutting. The holes are too small to be lasercut. So they may be marked and drilled by hand to 3,4 mm. After putting all the parts together you can sew it together at the poins wher you can see the mating-noses from the outside, or you can drill threads and use M3 screws like the original wooden housing.

For my machine, afer some sanding and cleaning the whole frame was sandblasted with glass-perls to have a nice looking housing.

Finally the holes for the bearings and the vertical axes need to be reamed by a hand reamer 12 H7 or 16 H7.

I used some Loctite 641 retaining compound to fix the bearings into the holes. It would be even better to ream the holes with a Reamer in 16 K7 or M7 and press the bearings in, but they're hard to get and quite expensive.