Flex_link 3D for print

3358 Views 3 Likes 0 Downloads Download the piece here from 3dforprint

How we printed it

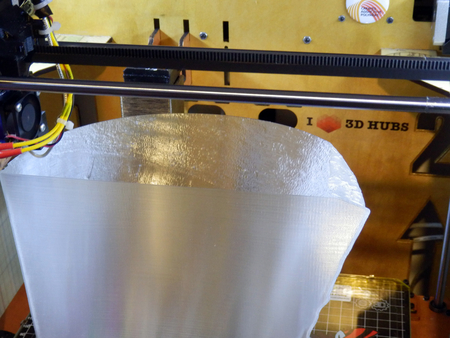

We have printed the parts with nGen_FLEX on a Ultimaker 2+ with a 0.8 millimeter diameter nozzle, 30% infill and a brim of at least 10 perimeters. The printer does require proper bed adhesion materials such as LokBuild (which we used) or BuildTak. To ensure enough strength and flexibility, we have printed each part with 7 perimeters and a 0,8 millimeters layer width on a resolution of 0.2 millimeters. The printed parts are stronger this way since they make use of the print direction.

Print slow to ensure proper layer adhesion and cooling for the overhangs. It is possible to print them with support, but the surface quality does not differ that much from printing without supports. Slow printing will also help to prevent complete warping of the parts, which will happen during the printing process. If it is possible, try to enclose the printer from the front to make sure that the surrounding temperature does not impact the print. Also, it is advised to "mirror" the connectors for the other side of the chair in order to have a matching finish on the printed parts.

After printing only the brim has to be removed, together with possible excess material depending on your retraction settings. Every component also has to be checked on the amount of warping, since the parts will warp due to the properties of nGen_FLEX.

How to make the plywood panels

To make the chair you need some 18 millimeters thick plywood which you can buy at almost any hardware store or wood shop. Other materials might also work but we only tested with plywood.

This wood has to be cut in the following measurements:

320mm x 500mm

385mm x 500mm

390mm x 500mm

395mm x 500mm

515mm x 500mm

632mm x 500mm

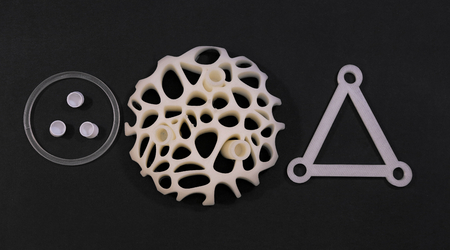

Afterwards, the marking tool included in the files was printed in PLA with standard settings and used to mark the gaps in the wood that needed to be cut. The tool works by placing it on a corner of a panel and is designed to be used for all corners. For reference to the correct geometry, we included the technical drawings in the files.

The tool has taken pencil or pen width into account, and it is advised to cut on the inside of the line in order to get the final geometry to the proper size using other tools or sandpaper. We then used a higher grade sandpaper to make the wood more smooth and used standard wood oil to protect the surface This will make it a bit darker and let the grain come out more.

We have also provided DXF files for the panels for when laser cutting is an available option.

How to assemble

For the assembly, we have provided an assembly manual. The assembly has been done using a small hammer to set the printed pieces into place. Since it is nGen_FLEX, it can take a hit and the flexibility will make sure it fits perfectly around the wood. It is advised to assemble it with two people, so it can be done quickly and without any problems.

Some more information

This design has been made to make people use their printers and colorFabb materials for actual functional products and to let others that are not familiar with 3D printing see what is possible. The chair has been engineered to support a maximum load of 150 kilograms but a lower load is of course preferable. The printed parts itself are designed with a safety factor that resulted from active testing of the material.

Since we tried to use the material as efficiently as possible all parts can be printed with 3 spools of nGen_FLEX filament. This does not, however, take into account possible failed prints, and therefore a backup spool might be necessary. For more information on the material please visit the colorFabb website.

For further reading into the development process, you can find our blog posts about this chair at learn.colorfabb.com

No further testing was done regarding safety and/or durability. Therefore we can not take or accept any responsibility for anything a user does (prints) with the filament.

Next, ...we have used 18 millimeters thick plywood which has been cut to the specific dimensions.

Designer

colorFabb3d model description

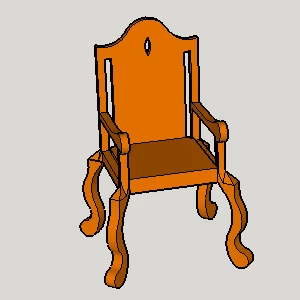

This is a chair everyone with a printer and some nGen_FLEX filament can make at home! Using the printed parts in combination with plywood you can buy ...at any hardware store it becomes possible to make this chair yourself! Designed by Niels van ValburgHow we printed it

We have printed the parts with nGen_FLEX on a Ultimaker 2+ with a 0.8 millimeter diameter nozzle, 30% infill and a brim of at least 10 perimeters. The printer does require proper bed adhesion materials such as LokBuild (which we used) or BuildTak. To ensure enough strength and flexibility, we have printed each part with 7 perimeters and a 0,8 millimeters layer width on a resolution of 0.2 millimeters. The printed parts are stronger this way since they make use of the print direction.

Print slow to ensure proper layer adhesion and cooling for the overhangs. It is possible to print them with support, but the surface quality does not differ that much from printing without supports. Slow printing will also help to prevent complete warping of the parts, which will happen during the printing process. If it is possible, try to enclose the printer from the front to make sure that the surrounding temperature does not impact the print. Also, it is advised to "mirror" the connectors for the other side of the chair in order to have a matching finish on the printed parts.

After printing only the brim has to be removed, together with possible excess material depending on your retraction settings. Every component also has to be checked on the amount of warping, since the parts will warp due to the properties of nGen_FLEX.

How to make the plywood panels

To make the chair you need some 18 millimeters thick plywood which you can buy at almost any hardware store or wood shop. Other materials might also work but we only tested with plywood.

This wood has to be cut in the following measurements:

320mm x 500mm

385mm x 500mm

390mm x 500mm

395mm x 500mm

515mm x 500mm

632mm x 500mm

Afterwards, the marking tool included in the files was printed in PLA with standard settings and used to mark the gaps in the wood that needed to be cut. The tool works by placing it on a corner of a panel and is designed to be used for all corners. For reference to the correct geometry, we included the technical drawings in the files.

The tool has taken pencil or pen width into account, and it is advised to cut on the inside of the line in order to get the final geometry to the proper size using other tools or sandpaper. We then used a higher grade sandpaper to make the wood more smooth and used standard wood oil to protect the surface This will make it a bit darker and let the grain come out more.

We have also provided DXF files for the panels for when laser cutting is an available option.

How to assemble

For the assembly, we have provided an assembly manual. The assembly has been done using a small hammer to set the printed pieces into place. Since it is nGen_FLEX, it can take a hit and the flexibility will make sure it fits perfectly around the wood. It is advised to assemble it with two people, so it can be done quickly and without any problems.

Some more information

This design has been made to make people use their printers and colorFabb materials for actual functional products and to let others that are not familiar with 3D printing see what is possible. The chair has been engineered to support a maximum load of 150 kilograms but a lower load is of course preferable. The printed parts itself are designed with a safety factor that resulted from active testing of the material.

Since we tried to use the material as efficiently as possible all parts can be printed with 3 spools of nGen_FLEX filament. This does not, however, take into account possible failed prints, and therefore a backup spool might be necessary. For more information on the material please visit the colorFabb website.

For further reading into the development process, you can find our blog posts about this chair at learn.colorfabb.com

No further testing was done regarding safety and/or durability. Therefore we can not take or accept any responsibility for anything a user does (prints) with the filament.

3d model print parameters

In total 3 650 gram spools of nGen_FLEX were used to print all the parts. This does not, however, as mentioned above, include failed prints.Next, ...we have used 18 millimeters thick plywood which has been cut to the specific dimensions.