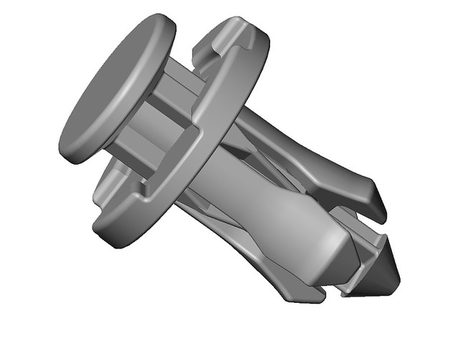

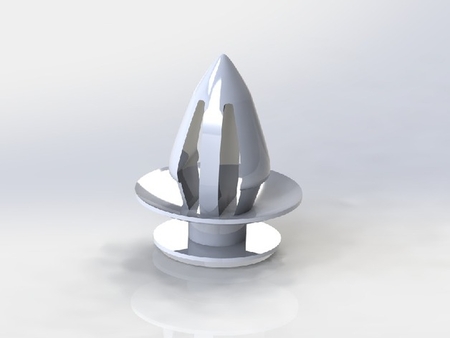

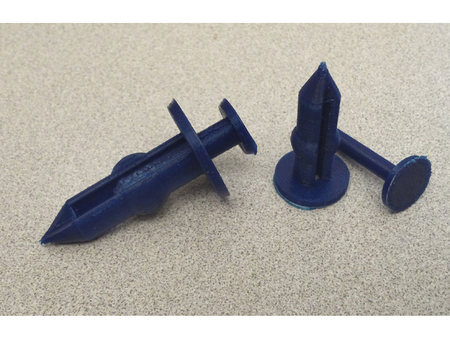

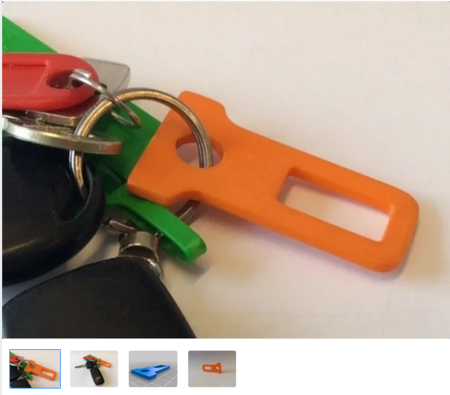

10mm automotive body trim rivet 3D for print

10623 Views 1 Likes 5 Downloads Download the piece here from 3dforprint

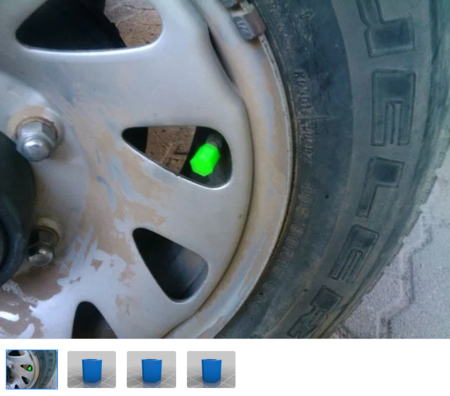

This is a nearly exact knock-off of the rivets from a 2016 Subaru, but will work for any car requiring a 10mm (3/8") fastener. These parts work interchangeably with their counterparts that came with the car.

Printing Considerations:

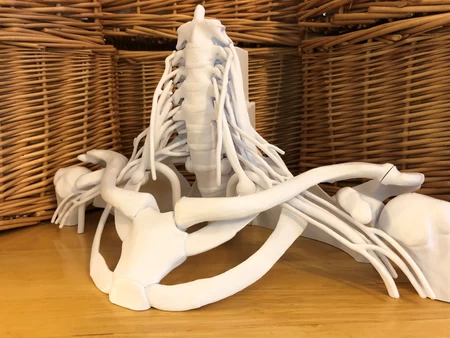

The female prints best on its side for strength at the base of its four teeth and will require some build support for such in your slicing program.. Printing it upright is easier, but the strength will be lost, and subject to the layer-to-layer bond strength, and the teeth will easily break.

I use Simplify3D for the ability to customize support structures.

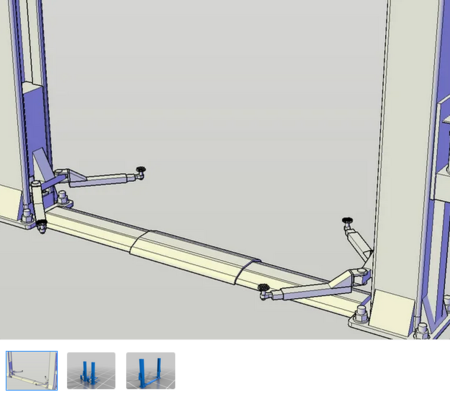

The female part seems to print better rotated 45 degrees so that two of the edges of the teeth are parallel to the bed and the narrow part of the head touches the raft/bed. Look at the image with the support and see where the head contacts the bed/raft. Also seems like printing at 0.1mm/layer is counter productive and 1.5mm or thicker is better. This part prints more reliably with a raft under it to anchor the narrow edge of the head disk feature.

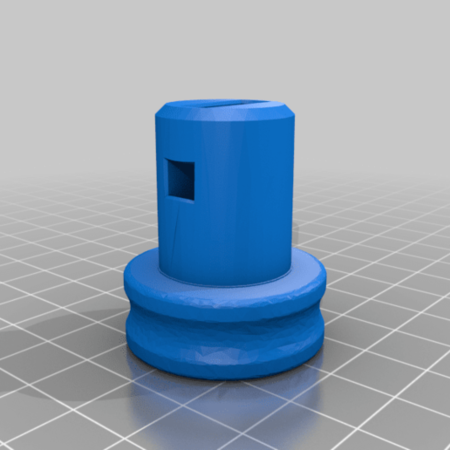

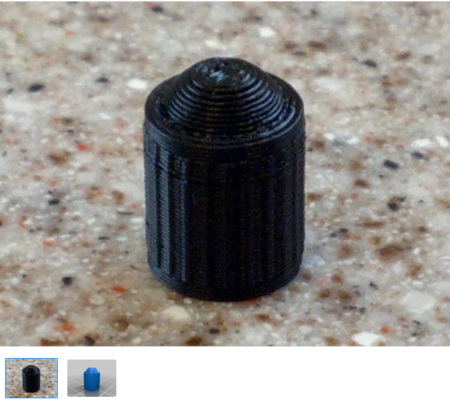

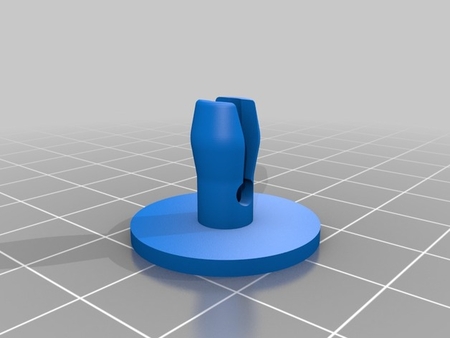

The male part seems to print better facing up with its head on the bed. Experimentation tells me this part requires NO support and I'll change the images that show support when I have a spare moment. It's so chunky and non-critical that the print orientation is NOT an issue.

In an effort to print the nicest version of these I printed them both facing up. They absolutely look and feel perfect, but the female version will quickly break where the teeth meet the base.

I was recently told by a user of this model that the female part prints well in TPU and that the flexibility overcomes the brittleness of the PLA or ABS and allows the female part to be built facing up with minimal support and results is a strong enough part. Not sure of the "shore" value of the TPU from the user who reported this.

Please add a LIKE if you think you will print and use this part!

PowerSpec

Printer:

PowerSpec 3D Pro

Rafts:

Yes

Supports:

Yes

Resolution:

any

Infill:

40% or higher with 4 shells

...

Filament_brand:

Inland

Filament_color:

any

Filament_material:

PLA

Notes:

Not sure how PLA will hold up under the hood of the car in the heat of the summer.

How I Designed This

Designed using dial calipers, with a magnifying ring-lamp to identify each part of the geometry, and then rendered in SolidWorks. Required adding a few planes and several axis to support polar array, mirror entities, and revolves. The majority of both parts were revolved sketches followed by various cuts to get the final shapes.

Designer

elhalpern3d model description

I had a bunch of broken rivet teeth, some missing male rivets, and needed to finish a car repair late at night after the local stores closed. So, I de...cided to model both parts of the rivet so I could reassemble the trim panels.This is a nearly exact knock-off of the rivets from a 2016 Subaru, but will work for any car requiring a 10mm (3/8") fastener. These parts work interchangeably with their counterparts that came with the car.

Printing Considerations:

The female prints best on its side for strength at the base of its four teeth and will require some build support for such in your slicing program.. Printing it upright is easier, but the strength will be lost, and subject to the layer-to-layer bond strength, and the teeth will easily break.

I use Simplify3D for the ability to customize support structures.

The female part seems to print better rotated 45 degrees so that two of the edges of the teeth are parallel to the bed and the narrow part of the head touches the raft/bed. Look at the image with the support and see where the head contacts the bed/raft. Also seems like printing at 0.1mm/layer is counter productive and 1.5mm or thicker is better. This part prints more reliably with a raft under it to anchor the narrow edge of the head disk feature.

The male part seems to print better facing up with its head on the bed. Experimentation tells me this part requires NO support and I'll change the images that show support when I have a spare moment. It's so chunky and non-critical that the print orientation is NOT an issue.

In an effort to print the nicest version of these I printed them both facing up. They absolutely look and feel perfect, but the female version will quickly break where the teeth meet the base.

I was recently told by a user of this model that the female part prints well in TPU and that the flexibility overcomes the brittleness of the PLA or ABS and allows the female part to be built facing up with minimal support and results is a strong enough part. Not sure of the "shore" value of the TPU from the user who reported this.

Please add a LIKE if you think you will print and use this part!

3d model print parameters

Printer brand:PowerSpec

Printer:

PowerSpec 3D Pro

Rafts:

Yes

Supports:

Yes

Resolution:

any

Infill:

40% or higher with 4 shells

...

Filament_brand:

Inland

Filament_color:

any

Filament_material:

PLA

Notes:

Not sure how PLA will hold up under the hood of the car in the heat of the summer.

How I Designed This

Designed using dial calipers, with a magnifying ring-lamp to identify each part of the geometry, and then rendered in SolidWorks. Required adding a few planes and several axis to support polar array, mirror entities, and revolves. The majority of both parts were revolved sketches followed by various cuts to get the final shapes.