Snowman pin walker 3D for print

4227 Views 2 Likes 0 Downloads Download the piece here from 3dforprint

In the event snow is a no show...

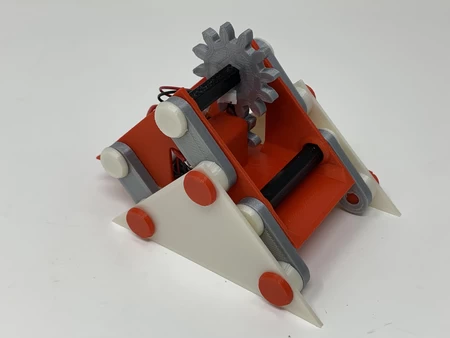

I designed, 3D printed and assembled "Snowman Pin Walker" u...sing components and assembly methods similar to my "Halloween Happy Ghost Pin Walker". Snowman Pin Walker is a snowman themed pin walker and, in comparison to the happy ghost, is quite large.

The center of mass for this model (as determined by Autodesk Fusion 360) is quite high, located at the fifth snowman "button" up from the base, at the center of the fore and aft / left and right extents of the model. In order to maintain side to side stability of the model, I designed the width, length and position of the feet on "Base.stl" for a N20 6VDC 100RPM motor operating at 3.7VDC. Motors with lower RPM ratings should work fine, but motors with higher RPM ratings, and / or operating the recommended motor at higher voltages, could induce side to side stability issues, or in other words, fall over.

I try to learn something new with each design I create, so in this model, prior to 3D printing the dual extrusion snowmen (I printed one in Tough PLA and one in PLA), I decided to enable the Cura 4.3.0 "Prime Tower" and "Ooze Shield" options to see how well these options improved the dual extrusion print quality. The time required to print the snowmen with these options enabled was around twelve hours each thus they easily qualified for "overnight" prints, but as shown in the next day photographs and videos of the snowmen, they came out of their ooze shields with no other clean up and with quite impressive results!

And as usual, I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to ask as I do make plenty of mistakes.

Designed using Autodesk Fusion 360, sliced using Cura 4.3.0, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker S5, and in Tough PLA on and Ultimaker 3+ Extended.

One final note, I receive no compensation in any form whatsoever for the design, equipment, purchased components and/or materials used in this model.

• One 3.7vdc 100ma Lithium Battery (https://www.adafruit.com/product/1570).

�...�� One JST PH 2-Pin Cable (https://www.adafruit.com/product/3814).

• One N20 6VDC 100RPM gear motor.

• One micro switch (Uxcell a12013100ux0116 High Knob 3P 2 Position 1P2T SPDT Vertical • Slide Switch, 0.5 Amp, 50V DC, 50 Piece, 3 mm).

You may also need to acquire a suitable battery charger.

I 3D printed the following components for this model at .15mm layer height, 20% infill, with support as noted:

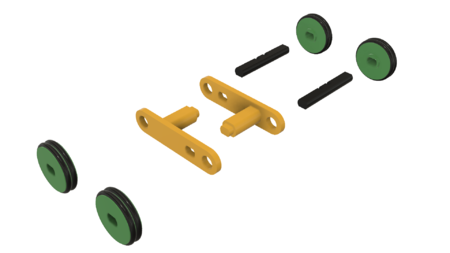

• Three "Axle, 8mm Head.stl".

• Two "Axle, 10mm Head.stl".

• One "Base, Snowman.stl" with support.

• Two "Bolt, Snowman.stl".

• One "Cam And Axle.stl".

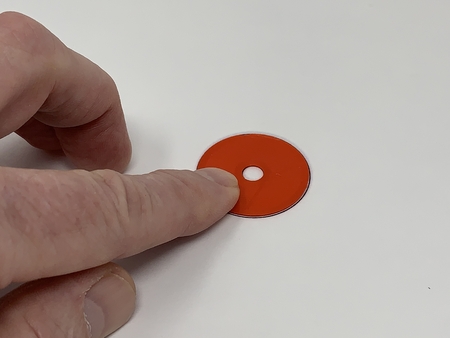

• One "Cam.stl".

• One "Gear, Crown, Axle.stl".

• One "Gear, Crown, Motor.stl".

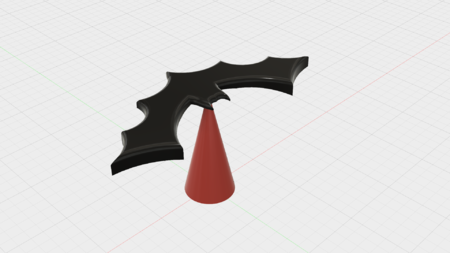

• One "Hat.stl".

• One "Mount, Snowman.stl".

• Two "Pin.stl".

• One "Seesaw.stl".

• One "Snowman, Single Extrusion.stl" or one "Snowman.3mf".

As mentioned, I printed the dual extrusion "Snowman.3mf" with the Cura 4.3.0 "Prime Tower" and "Ooze Shield" options enabled. Noting the photographs showing the snowman printed in Tough PLA on an Ultimaker 3+ Extended and in PLA on an Ultimaker S5, the "prime tower" appears in the right rear of each photo and the "ooze shield" surrounds each snowmen. The prime towers are used to remove any filament strands from the nozzle prior to each layer print (the strands appearing on the prime towers which would have been on the model). The ooze shields minimize oozing of the smaller dual extruded features such as the buttons and eyes. With both features enabled, the model requires an additional 1.49m (12g) of white filament and 1.76m (13g) of black filament on the Ultimaker 3+ Extended, and 2.06m (17g) of white filament and .98m (7g) of black filament on an Ultimaker S5, which is wasted material, but for me the wasted filament was worth the improvement. After removing each snowman from the build plate, I cut away the ooze shield using small modeling scissors.

This is a high precision print and assembly model using at times very small parts and in very tight spaces. Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on you printer, your printer settings and the colors you chose, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely certain that all build plate "ooze" is removed and that all edges are smooth. I used small jewelers files and plenty of patience to perform this step.

The model also uses threaded assembly, so I used a tap and die set (6mm by 1) for thread cleaning.

I used light machine oil for lubrication of the gears and axles.

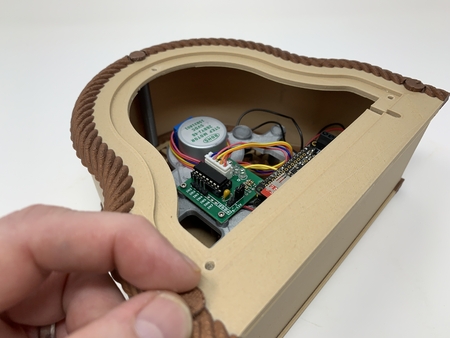

Wire the Snowman Motor, Switch and JST Connector.

To wire the snowman motor, switch and JST connector, I performed the following steps:

• Cut the wires on the JST connector to 40mm in length, then stripped and tinned the ends.

• Soldered the black wire from the JST connector to the motor "-" terminal.

• Soldered the red wire from the JST connector to one of the outside switch terminals.

• Soldered the center switch terminal to the motor "+" terminal.

After wiring, I connected the JST connector to the battery and operated the switch to turn the motor on and off.

Assemble the Base.

To assemble the base, I performed the following steps:

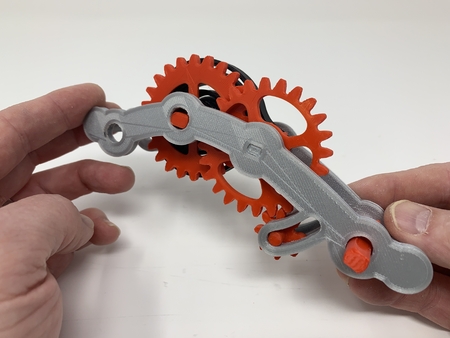

• Pressed the gear motor assembly into "Base.stl" such that the motor shaft was 3mm above the motor gear plate.

• Pressed "Gear, Crown, Motor.stl" onto the motor shaft.

• Slid "Mount, Snowman.stl" down from the top of the base assembly over the lower threaded hole and secured in place with two "Axle, 8mm.stl".

• Positioned "Gear, Crown, Axle.stl" centered over the small hole in the base assembly.

• Slid "Cam And Axle.stl" through larger upper hole in the base assembly, pressed through the axle crown gear, then out the smaller hole of the base assembly.

• Pressed "Cam.stl" onto the cam and axle 180 degrees out of phase with the cam and axle cam.

• Positioned one "Pin.stl" into the pin slot in the base assembly, slid the pin ring over the cam, then secured the pin in place with one "Axle, 10mm Head.stl".

• Positioned the remaining "Pin.stl" into the remaining pin slot in the base assembly, slid the pin ring over the cam, then secured the pin in place with the remaining "Axle, 10mm Head.stl".

• Manually rotated the motor gear until the seesaw driving pins were level.

• Positioned "Seesaw.stl" onto the front of the base assembly over the upper threaded hole and secured in place with the remaining "Axle, 8mm Head.stl".

• Secured the battery to the rear of the base assembly with doubled sided tape.

At this point, I connected the motor to a power supply in order to test the assembly. I lubricated and operated the assembly and noted the power consumption to be 12 to 18ma. With testing completed, I removed the power supply then connected the battery to the motor using the JST connectors.

Final Assembly.

For final assembly, I performed the following steps:

• Secured the switch to the inside of the foot using either one small dot of cyanoacrylate glue or a small strip of double sided tape.

• Slid "Snowman.3mf" (or "Snowman.stl") downward from the top of the base assembly until it contacted the body mount, aligned the snowman mount holes with the body mount holes, then secured the snowman to the body mount using two "Bolt, Snowman.stl".

• Double checked that the wiring did not interfere with the moving components.

• Attached "Hat.stl" to the assembly using small dots of thick cyanoacrylate glue.

And that is how I printed and assembled Snowman Pin Walker.

I hope you enjoyed it!

Designer

Greg Zumwalt3d model description

Another pin walking design, this one snowman themed.In the event snow is a no show...

I designed, 3D printed and assembled "Snowman Pin Walker" u...sing components and assembly methods similar to my "Halloween Happy Ghost Pin Walker". Snowman Pin Walker is a snowman themed pin walker and, in comparison to the happy ghost, is quite large.

The center of mass for this model (as determined by Autodesk Fusion 360) is quite high, located at the fifth snowman "button" up from the base, at the center of the fore and aft / left and right extents of the model. In order to maintain side to side stability of the model, I designed the width, length and position of the feet on "Base.stl" for a N20 6VDC 100RPM motor operating at 3.7VDC. Motors with lower RPM ratings should work fine, but motors with higher RPM ratings, and / or operating the recommended motor at higher voltages, could induce side to side stability issues, or in other words, fall over.

I try to learn something new with each design I create, so in this model, prior to 3D printing the dual extrusion snowmen (I printed one in Tough PLA and one in PLA), I decided to enable the Cura 4.3.0 "Prime Tower" and "Ooze Shield" options to see how well these options improved the dual extrusion print quality. The time required to print the snowmen with these options enabled was around twelve hours each thus they easily qualified for "overnight" prints, but as shown in the next day photographs and videos of the snowmen, they came out of their ooze shields with no other clean up and with quite impressive results!

And as usual, I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to ask as I do make plenty of mistakes.

Designed using Autodesk Fusion 360, sliced using Cura 4.3.0, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker S5, and in Tough PLA on and Ultimaker 3+ Extended.

One final note, I receive no compensation in any form whatsoever for the design, equipment, purchased components and/or materials used in this model.

3d model print parameters

I acquired the following non-3D printed components for this model:• One 3.7vdc 100ma Lithium Battery (https://www.adafruit.com/product/1570).

�...�� One JST PH 2-Pin Cable (https://www.adafruit.com/product/3814).

• One N20 6VDC 100RPM gear motor.

• One micro switch (Uxcell a12013100ux0116 High Knob 3P 2 Position 1P2T SPDT Vertical • Slide Switch, 0.5 Amp, 50V DC, 50 Piece, 3 mm).

You may also need to acquire a suitable battery charger.

I 3D printed the following components for this model at .15mm layer height, 20% infill, with support as noted:

• Three "Axle, 8mm Head.stl".

• Two "Axle, 10mm Head.stl".

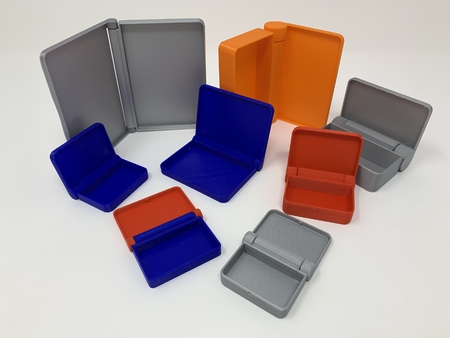

• One "Base, Snowman.stl" with support.

• Two "Bolt, Snowman.stl".

• One "Cam And Axle.stl".

• One "Cam.stl".

• One "Gear, Crown, Axle.stl".

• One "Gear, Crown, Motor.stl".

• One "Hat.stl".

• One "Mount, Snowman.stl".

• Two "Pin.stl".

• One "Seesaw.stl".

• One "Snowman, Single Extrusion.stl" or one "Snowman.3mf".

As mentioned, I printed the dual extrusion "Snowman.3mf" with the Cura 4.3.0 "Prime Tower" and "Ooze Shield" options enabled. Noting the photographs showing the snowman printed in Tough PLA on an Ultimaker 3+ Extended and in PLA on an Ultimaker S5, the "prime tower" appears in the right rear of each photo and the "ooze shield" surrounds each snowmen. The prime towers are used to remove any filament strands from the nozzle prior to each layer print (the strands appearing on the prime towers which would have been on the model). The ooze shields minimize oozing of the smaller dual extruded features such as the buttons and eyes. With both features enabled, the model requires an additional 1.49m (12g) of white filament and 1.76m (13g) of black filament on the Ultimaker 3+ Extended, and 2.06m (17g) of white filament and .98m (7g) of black filament on an Ultimaker S5, which is wasted material, but for me the wasted filament was worth the improvement. After removing each snowman from the build plate, I cut away the ooze shield using small modeling scissors.

This is a high precision print and assembly model using at times very small parts and in very tight spaces. Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on you printer, your printer settings and the colors you chose, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely certain that all build plate "ooze" is removed and that all edges are smooth. I used small jewelers files and plenty of patience to perform this step.

The model also uses threaded assembly, so I used a tap and die set (6mm by 1) for thread cleaning.

I used light machine oil for lubrication of the gears and axles.

Wire the Snowman Motor, Switch and JST Connector.

To wire the snowman motor, switch and JST connector, I performed the following steps:

• Cut the wires on the JST connector to 40mm in length, then stripped and tinned the ends.

• Soldered the black wire from the JST connector to the motor "-" terminal.

• Soldered the red wire from the JST connector to one of the outside switch terminals.

• Soldered the center switch terminal to the motor "+" terminal.

After wiring, I connected the JST connector to the battery and operated the switch to turn the motor on and off.

Assemble the Base.

To assemble the base, I performed the following steps:

• Pressed the gear motor assembly into "Base.stl" such that the motor shaft was 3mm above the motor gear plate.

• Pressed "Gear, Crown, Motor.stl" onto the motor shaft.

• Slid "Mount, Snowman.stl" down from the top of the base assembly over the lower threaded hole and secured in place with two "Axle, 8mm.stl".

• Positioned "Gear, Crown, Axle.stl" centered over the small hole in the base assembly.

• Slid "Cam And Axle.stl" through larger upper hole in the base assembly, pressed through the axle crown gear, then out the smaller hole of the base assembly.

• Pressed "Cam.stl" onto the cam and axle 180 degrees out of phase with the cam and axle cam.

• Positioned one "Pin.stl" into the pin slot in the base assembly, slid the pin ring over the cam, then secured the pin in place with one "Axle, 10mm Head.stl".

• Positioned the remaining "Pin.stl" into the remaining pin slot in the base assembly, slid the pin ring over the cam, then secured the pin in place with the remaining "Axle, 10mm Head.stl".

• Manually rotated the motor gear until the seesaw driving pins were level.

• Positioned "Seesaw.stl" onto the front of the base assembly over the upper threaded hole and secured in place with the remaining "Axle, 8mm Head.stl".

• Secured the battery to the rear of the base assembly with doubled sided tape.

At this point, I connected the motor to a power supply in order to test the assembly. I lubricated and operated the assembly and noted the power consumption to be 12 to 18ma. With testing completed, I removed the power supply then connected the battery to the motor using the JST connectors.

Final Assembly.

For final assembly, I performed the following steps:

• Secured the switch to the inside of the foot using either one small dot of cyanoacrylate glue or a small strip of double sided tape.

• Slid "Snowman.3mf" (or "Snowman.stl") downward from the top of the base assembly until it contacted the body mount, aligned the snowman mount holes with the body mount holes, then secured the snowman to the body mount using two "Bolt, Snowman.stl".

• Double checked that the wiring did not interfere with the moving components.

• Attached "Hat.stl" to the assembly using small dots of thick cyanoacrylate glue.

And that is how I printed and assembled Snowman Pin Walker.

I hope you enjoyed it!