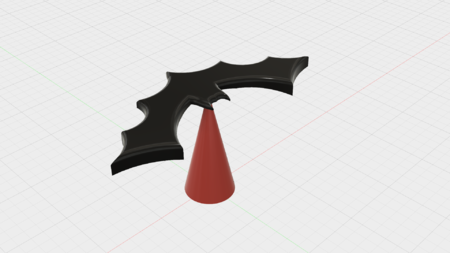

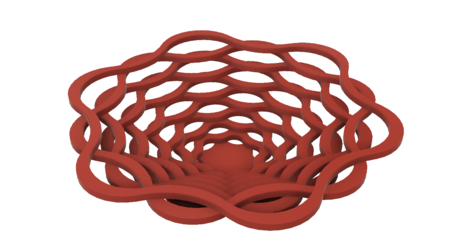

Tensegrity 3D for print

5401 Views 1 Likes 0 Downloads Download the piece here from 3dforprint

I really do need to get out from under my rock more often...

Many "tensegrity" styled chairs, tables and Lego m...odels have been showing up in my "suggested video" feed as of late and I must admit, I had never heard of tensegrity and as such had no clue what it meant. So I watched a few of the videos in my feed on the subject, and decided to try my hand at designing, 3D printing and assembling a small and simple tensegrity model.

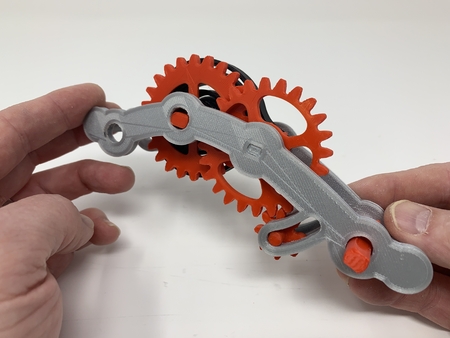

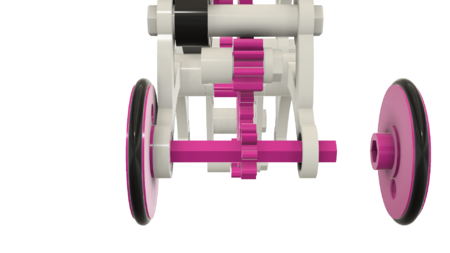

This tensegrity ("tensional integrity") model is entirely 3D printed including the three longer "print in place" outer chains and the single "print in place" shorter center chain. And what makes these chains so important? Well, while the three outer chains hold the top and bottom together (compression), at the same time the single center chain pulls the top and bottom apart (tension). With proper chain length design, the model compression and tension forces are balanced and thus the model appears to "float". And why are 3D printed chains more useful than string or twine? By using Autodesk Fusion 360, I was able to design 3D printed chains that were precise enough in length to balance the compression / tension forces required by this model, as opposed to the trial and error string / twine assembly requiring numerous adjustments. And after printing and assembling quite a few copies of this model, the 3D printed chains indeed proved to be much easier to assemble than my string/twine versions, so I stuck with the chains.

As usual I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to ask as I do make plenty of mistakes.

Designed using Autodesk Fusion 360, sliced using Cura 4.6.1, and 3D printed in PLA on an Ultimaker 2+ Extended, an Ultimaker 3 Extended and an Ultimaker S5.

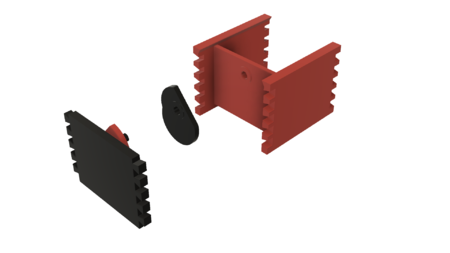

Parts.

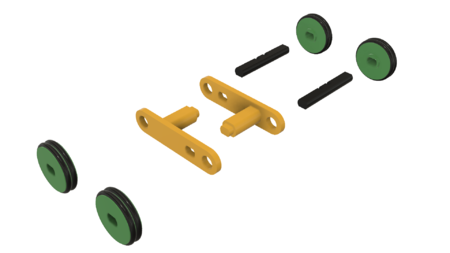

I 3D printed all parts at .15mm layer height with 100% infill. I printed one "Base.stl", three "Chain (Long).stl", ...one "Chain (Short).stl", two "Pin (Long).stl", six "Pin (Short).stl" and one "Top.stl".

This model is a precision print due to the small parts involved (the "Pin" components are 2mm in diameter) and the "print in place" chains (.5mm tolerance). I printed all pins at the same time using a brim for hold down. Once printed, I removed the pins from the brim and carefully filed the build plate end of the pins smooth.

Assembly.

To assemble "Tensegrity", I performed the following steps:

• Attached one "Chain (Long).stl" to "Top.stl" long chain mount using one "Pin (Short).stl".

• Attached the remaining two long chains to the top long chain mounts using two more short pins.

• Attached "Chain (Short).stl" to the top assembly short chain tower using one "Pin (Long).stl".

• Attached the free end of the short chain to the short chain tower on "Base.stl" using a long pin.

• Attached the free ends of the two rear long chains to the rear chain mounts on the top.

• Attached the free end of the front long chain to the front chain mount on the top.

And that is how I 3D printed and assembled "Tensegrity".

I hope you enjoyed it!

Designer

Greg Zumwalt3d model description

A "tensional integrity" model.I really do need to get out from under my rock more often...

Many "tensegrity" styled chairs, tables and Lego m...odels have been showing up in my "suggested video" feed as of late and I must admit, I had never heard of tensegrity and as such had no clue what it meant. So I watched a few of the videos in my feed on the subject, and decided to try my hand at designing, 3D printing and assembling a small and simple tensegrity model.

This tensegrity ("tensional integrity") model is entirely 3D printed including the three longer "print in place" outer chains and the single "print in place" shorter center chain. And what makes these chains so important? Well, while the three outer chains hold the top and bottom together (compression), at the same time the single center chain pulls the top and bottom apart (tension). With proper chain length design, the model compression and tension forces are balanced and thus the model appears to "float". And why are 3D printed chains more useful than string or twine? By using Autodesk Fusion 360, I was able to design 3D printed chains that were precise enough in length to balance the compression / tension forces required by this model, as opposed to the trial and error string / twine assembly requiring numerous adjustments. And after printing and assembling quite a few copies of this model, the 3D printed chains indeed proved to be much easier to assemble than my string/twine versions, so I stuck with the chains.

As usual I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to ask as I do make plenty of mistakes.

Designed using Autodesk Fusion 360, sliced using Cura 4.6.1, and 3D printed in PLA on an Ultimaker 2+ Extended, an Ultimaker 3 Extended and an Ultimaker S5.

3d model print parameters

Materials and methodsParts.

I 3D printed all parts at .15mm layer height with 100% infill. I printed one "Base.stl", three "Chain (Long).stl", ...one "Chain (Short).stl", two "Pin (Long).stl", six "Pin (Short).stl" and one "Top.stl".

This model is a precision print due to the small parts involved (the "Pin" components are 2mm in diameter) and the "print in place" chains (.5mm tolerance). I printed all pins at the same time using a brim for hold down. Once printed, I removed the pins from the brim and carefully filed the build plate end of the pins smooth.

Assembly.

To assemble "Tensegrity", I performed the following steps:

• Attached one "Chain (Long).stl" to "Top.stl" long chain mount using one "Pin (Short).stl".

• Attached the remaining two long chains to the top long chain mounts using two more short pins.

• Attached "Chain (Short).stl" to the top assembly short chain tower using one "Pin (Long).stl".

• Attached the free end of the short chain to the short chain tower on "Base.stl" using a long pin.

• Attached the free ends of the two rear long chains to the rear chain mounts on the top.

• Attached the free end of the front long chain to the front chain mount on the top.

And that is how I 3D printed and assembled "Tensegrity".

I hope you enjoyed it!