Zero gravity extruder by gudo & neotko - for um2 and umo+2 3D for print

6883 Views 3 Likes 0 Downloads Download the piece here from 3dforprint

ZGE Authors

ZGE Idea and des...ign & development by Charly - Gudo

Crazy Ideas and ZGE Logo by Sebas - Neotko

Much still to write about how to print this, assemble and use it correctly.

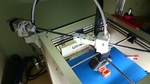

For now Check this OLD VIDEOS (REMEMBER THEY ARE OLD and they show OLD version assembly, but should give some hits to the pro users)

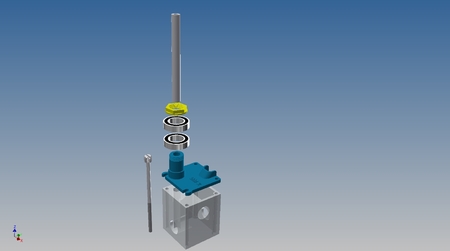

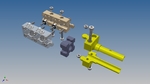

There's a STL with the Whole ZGE Assembled with the ZGE Shorthead, USE that to understand where goes everything.

There are Step files for everything, EXCEPT the Gudo-SliderUJoint system and the ShortZGE main part.

For any question, ask on the forum, not here, otherwise Gudo or I won't be able to answer properly.

General FAQ

Can I use other bearings?

NO. There's much math and simulations and beta testing on all the parts, if you fell like changing something just to save a buck, then this isn't the extruder for you, sorry!

Can I use a shorter square rod?

NO. I did bang Gudo with this many times, he is just so patient and explained me over and over how and why it can't. Basically that's the correct size for a umo/um2. Can you use 400 instead of 390mm, yea you can. But 390mm is the perfect length so it doesn't pick an eye while moving or hits you, and also is the length that allows the slider part to have always full contact with the square rod. So, like I said before, file the tip, because metal can hurt. (It never ever happened to me and I do look at the printer like a mad men when printing to debug stuff).

Could I move the holder to the other corner?

Yes, print it mirroed (that's something I did ask at the beginning, but after using it on the Left side I would not change it, it just make's sense... Hard to explain..

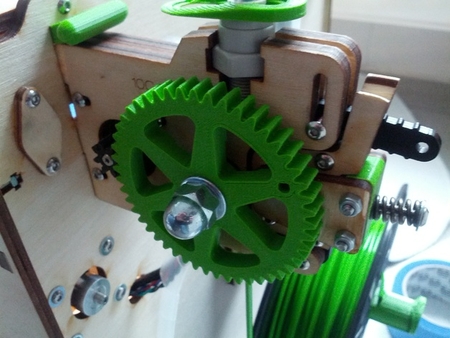

Can I use a cheaper drivegear?

NO (well you actually could if you redesign most of the stuff, but if you just want to extrude without quality you can do it by hand )

Can I just print it on ABS or PLA, or China cheap PLA?

NO. ABS for example size changes a lot, it can't get as much flex torsion without deforming as platec/greentec. Ofc if you thing you can, just do it, but don't come here asking why it fails Also the material used must be as precise as possible, that something that only good brands give. You wan't to have as many things under- control as possible when printing printing this with a bowden since the tolerances are quite hard. Short answer, we recommend Greentec / Platec for hightemp and strength.

Could I avoid to print the Flexible material parts?

Oh yes, I forgot, there are parts that actually need to be printed on flexible materials like ninjaflex, recreus and a semiflex material. WHY? Just because (will explain all this on the video/tutorial). Most of them you can actually print them after installing the system, but also, well you can print them one by one very slow until you get the zge working

Why the motor holder moves a bit when printing?

Because the system compensates the extrusion forces to avoid as much motion transmission to the printhead. Also, better the motor holder than the printhead, right?

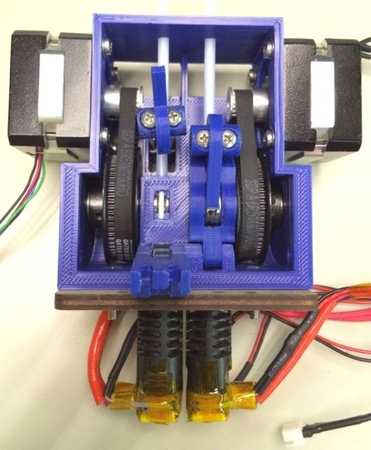

I have a dual printer, I wan't to use this!?

That's actually doable, Gudo even made a design that could work on a UM3. But... More or that someday. Basically we don't want to just make stuff that could work, but stuff that actually put something interesting on the table. There are many factors beyond making the extruder work on a um3 than just making it. Gudo actually I think did cover all of them, but then there's the part of the firmware. The UM3 firmware need's quite a lot knowhow to actually change parameters like Extrusion retraction while changing tools, prime amount, retraction amount, esteps, etc etc etc. So change this parameters on a um3 the user would need to know much knowhow to do stuff on linux without bricking the machine (editing stuff is really easy in the end but is a giant leap for most users). So for now we choose not to, but is there, if UM or maybe a modder makes a easy way to access the Machine Json files and edit them, then we might release it. Just because, it doesn't make sense to release stuff just for releasing stuff. Also, there's a big problemo for flexibles on um3, and that's the gap of air on top of the cores while they rest on the printhead.. So, could it work? Sure, but would it work everytime? That's the question... So, short answer, not yet.

More FAQ And important points about ZGE

Why we made it

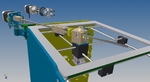

Gudo and Neotko are moving forward this extruder because we are always pursuing quality, speed and precision. Bowden is a lightweight solution that creates quite a number of handicaps, like for example hysteresis (filament compression due pressure) making it impossible to actually control the extrusion. With ZGE Direct Drive this is now posible, for 1.75mm filaments and 2.85mm, without any compromise on Extrusion horse power.

Why don’t we sell it atm

Gudo and I (Neotko) have other interest than just selling upgrades. Is a nice idea, but we been crunching numbers and isn’t something we would love to be doing on the short time. I have a business and is starting to work and it demands my full time (except weekends where I try to keep improving every bit of the printer). Also isn’t that easy, to make a comercial version of the ZGE would requiere most probably a mold, and that’s freaking expensive, delivery, stock, gudo making sliders, me printing all the other parts, and that could be a nice dream but we don’t have a 100 printers farm to do it right, and sincerely is great to not need to defend something that you want to 'sell' it keeps the mind objective and fresh to new ideas.

So we have choose the YDIY (You Do It Yourself) path. I will make videos of how to print and assemble the key parts that requiere extreme love and care to do them right. Gudo I think can provide for some individuals the key parts, but don’t

overwhelm him, if you don’t get one, you need to DIY.

The good

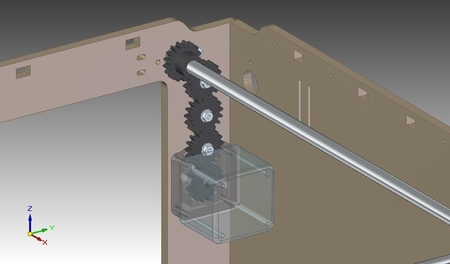

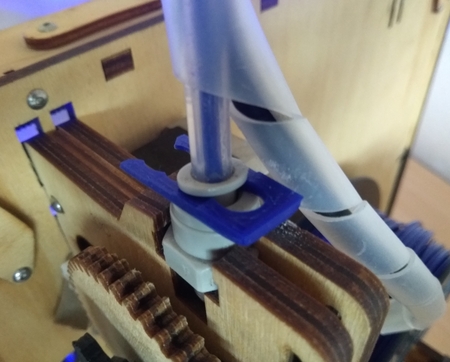

It freaking works, it extrudes beautifully, it keeps working and working and delivering repetition and amazing precision even with flexibles. Bondtech dualdrive has a lot on that, it could be done with a lesser quality extruder gear, but it would give troubles, bondtech does work and work and work. It grinds a bit, NO, it pushes the filament over and over (and we get Zero commission from bondtech on this!). The system moves a 390mm square shaft of 4mm square. This was the first challenge. I have been testing a 3x3 thinner rod and it works beautifully, but it will only be of use for 1.75mm guys.

1.75mm requieres less heat to extrude, less pressure, but also it has a drawback, it need’s more rotation on the drive gear, this means more stuff moving. That’s why a 3x3mm is better, because it delivers less noise to the weak um head (more on that latter)

2.85mm requieres more heat to extrude, more pressure but also has the advantage of less rotation on the drivegear, this means less noise translated to the printhead, but more force. So for this the best is a 4x4 square shaft.

The Bad

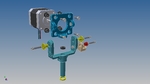

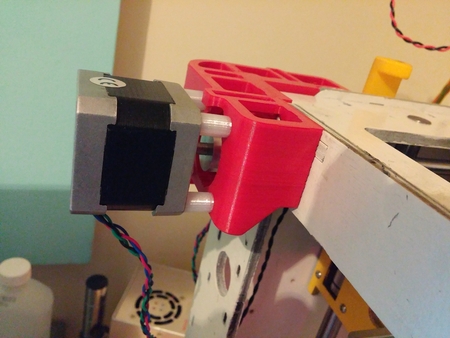

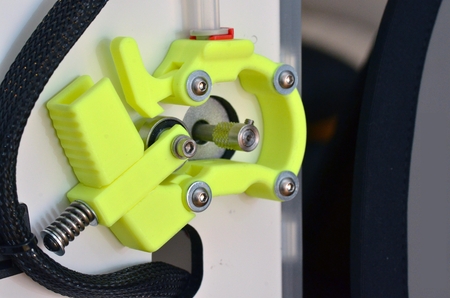

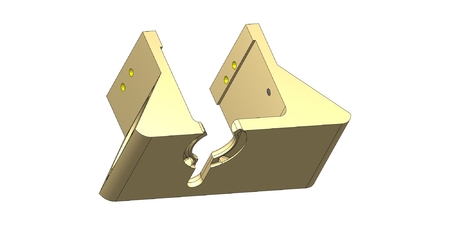

The punny UM2 hotend. We are using a hotend designed specifically for bowden, and bowden has one advantage, remove pressure and movement on the printhead, that’s why any single force done on the printhead (even a wooble bowden shacking) can add noise to the prints. And for the ZGE this means that every rotation on the drivegear can, since the head has very easy to bend and flexible shafts, translate tinny bits on Z noise. Does this Z noise is perceptible? Well, is hard to see, but is there, most users that don’t have a perfect Z might not notice this, but since I’m a crazy guy I did noticed it. The first version was much more dependent of a perfect square shaft. Gudo made an amazing improvement to this problem developing a printable UJoint system that allows to remove the imperfections of a inexpensive rod (more on this later). And just yesterday, I got an idea (star medal for me on this since I’m really proud) we changed a part to be printed on flexible material removing almost 50% of the noise and making the prints look even better.

So... Does it print better than a Bowden? It freaking does. Does it has a bit more of noise on Z? Yes it does, sorry, that’s how things are. UM2 head, even the 8mm shafts can ‘bend’ and they keep wobbling making them very susceptible to Pressure from the drive-gears to the head. Every retract/extrude is a sudden move, that translates this sudden moves to the printhead. But with this last update the problem is hard to see, and most of normal users won’t ever see it.

The Ugly

To print a ZGE you need aprox 5h for the most delicate parts (slider+driveshaft) and they will need some post-processing. Add one hour of assembly for this part, that must be done with love and not by brute force. Also you do need a hightemperature

material, like greentec, platec. Just because this part get’s heat from the bed, so if you print at 60, the air will get there to 35C, and that + extrusion forces = bends. The Extruder head also should be greentec, platec. Is a very amazing material (we also get zero commission on this), but need’s hairspray on the bed and brims, and cleaning. I made a good article about how to add custom brims to the support, read it, read it again, and use it. You need all the parts to be printed perfect. More than 50mm/s can ruin the print and will add time to manual cleaning, that is less reliable than a 3dprinter.

You will need to calibrate your printer to the 0.02-0.03 closeness to the measures we will show as base. Just like Gudo and I did, we used one of the parts, print it and with a digital caliper of at least 2 decimal points, I did print the object 3 times, with different Horizontal Expansion values of -0.02 -0.03 -0.05. For me the winner was the 0.02. So as you can guess, the difference from printing it right or wrong is very very small. You need to keep that in mind for the main part of the ZGE, since is the most delicate part. First time I print one I did it horrible, and after printing 20-23 I thing I have enough practice to make a perfect ZGE slider+shaft.

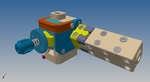

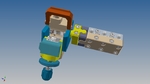

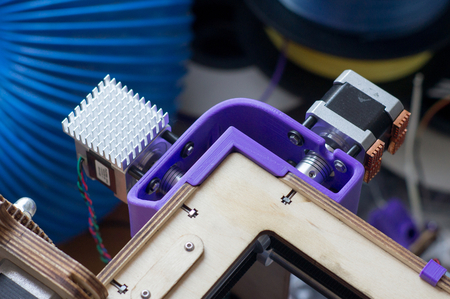

The rest of the parts, need screws, nothing hard to find. There are two types of heads, one is more compact but need’s some special small 4mm mini shafts. The other, is more complex to assemble and is based on my Neotko-FatIRobertI extruder. Gudo also added a tension selector (very cool) to have 3 basic positions easy interchangeable. But is much complex to print. Also is taller... That... Well, shorter means less vibrations, taller more vibrations... Yea there are many many factors that we have take into account before posting this.

We still need to talk Gudo and I of what basic version we release. Most probably the slider, they key part, won’t have a step file release, but the others might, or not. The important is that all the parts will be easy to print, except the slider (the slider, as I said over and over here must be printed with love and finished more or less by hand).

The Main key parts you will need to get to DIY.

First of all, the square rod of 390mm, there are shops on ebay that cut on demand, but try to be ware that the tip you need to soft it (file it) for safety! You don’t want to loose an eye because you didn’t hear us out right?

For precision square shafts (they call them Key Steel or Parallel Key) the max length we where able to find is 350mm (on misumi) so that means that it would not work. It need’s to be a minimum of 390mm. Gudo might be able to provide this to some users, but again, ask once, if he doesn’t answer he is busy doing something more interesting, don’t hammer it. And you will need to pay for it, you know, square shafts don’t grow on trees.

A shorter smaller screw. You know the four screws that hold your hotend? Well, one must be shorter, like 4mm taller, you can ‘sew’ it yourself indeed. Again, not easy to find. Gudo is amazing and he made me a few with the first kits he made for me.

Bondtech Drive gears for 1.75 or 2.85 you need the 8mm shaft dia, with 4mm -

24-25mm long shaft for the mirror gear.

Motor. I have use, and I keep using, the UMO motor without any geared solution. For 1.75 works perfectly. For 2.85 the best (until one of the beta testers install it and test the motor I sent) is a Bondtech 5.18 geared nema. It works and works.

I have a shop, I want to sell it!

Contact Gudo for this, you two might get along and do some business. I personally would love to see this extruder on every printer out there. But mind one thing, no shortcuts, no china quality. If you thing you are decent, come talk with Gudo.

I want it for my printer!

Our dream is to have this on as many printers as possible, a Bowden-free world. If you are a 3d printer maker contact us and we will study making a version of our ZGE for your machine. But remember this is Open Source, so we will focus on Open Source machines like UM, BCN, and probably others.

If we don’t support your printer, give us time, we are just two guys that love 3d printing and making our printers as precise as possible. Contact your printer company, if they give us access to your files we might do it! And ofc if you have a Solid Robust No Woobly printer, we are interested But ofc, Maybe Gudo just make's a better printer out of this UM.... But that's a history for other day

- BONDTECH Dual Gears kit 1.75mm or 2.85mm/shaft dia 8mm

* important if use

Iroberti order the 4mm x 22mm driven gear pin

Short ZG...E order the 4mm x 25mm driven gear pin

- 4x4mm precision Square Rod - Steel or Stainless steel - 390/400 mm lenght

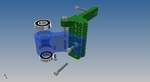

- ZGE Bearings

8x - 3x8x3 ZZ (slider)

2x - 8x16x5 ZZ (extruder)

2x - 10x19x5 ZZ (frame motor holder)

2x - 12x21x5 ZZ (print head extruder holder)

- Fastener metric M3 SOCKET HEAD BOLTS & NUTS

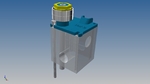

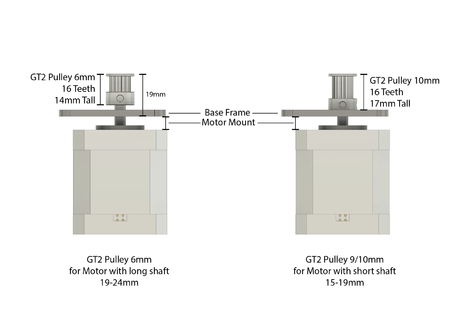

- ADJUSTABLE FRAME MOTOR HOLDER

2x 20mm (UM2 frame)

2x 18mm (UMO frame)

2x 8mm + nut

1x 35mm + nut

- MOTOR SHAFT/SQUARE ROD COUPLER

4x 12mm + M3 nut

- STEPPER MOTOR HOLDER

4x 10mm

3x 16mm + nut

- SLIDER

10x 18mm + nut

- GEAR DRIVE SHAFT

2x 18mm + nut

- EXTRUDER

- IRoberti version

* 3x 8mm Hexagon socket button head (or Philips equivalent)

3x 30mm + nut

- SHORT version

* 4x 8mm Hexagon socket button head (or Philips equivalent)

1x 30mm + nut

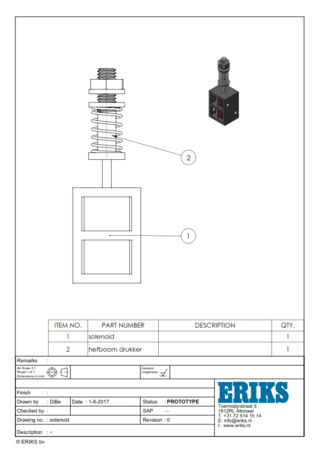

- SPRING SREW for the 2 Extruder versions

1x 35/40 mm HEXAGONAL head + nut

- Short ZGE Spring pressure guide

2x 4mm x 18mm pin

Designer

Neotko / Sugarpop!3d model description

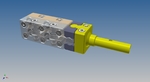

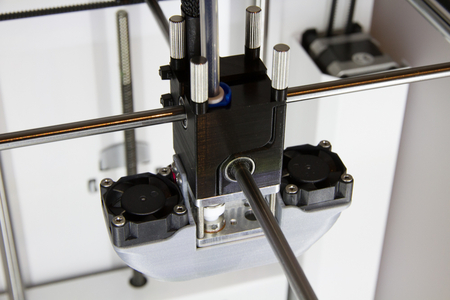

Direct Drive system that removes almost all the motor weight without penalty on torque extrusion. Still in development.ZGE Authors

ZGE Idea and des...ign & development by Charly - Gudo

Crazy Ideas and ZGE Logo by Sebas - Neotko

Much still to write about how to print this, assemble and use it correctly.

For now Check this OLD VIDEOS (REMEMBER THEY ARE OLD and they show OLD version assembly, but should give some hits to the pro users)

There's a STL with the Whole ZGE Assembled with the ZGE Shorthead, USE that to understand where goes everything.

There are Step files for everything, EXCEPT the Gudo-SliderUJoint system and the ShortZGE main part.

For any question, ask on the forum, not here, otherwise Gudo or I won't be able to answer properly.

General FAQ

Can I use other bearings?

NO. There's much math and simulations and beta testing on all the parts, if you fell like changing something just to save a buck, then this isn't the extruder for you, sorry!

Can I use a shorter square rod?

NO. I did bang Gudo with this many times, he is just so patient and explained me over and over how and why it can't. Basically that's the correct size for a umo/um2. Can you use 400 instead of 390mm, yea you can. But 390mm is the perfect length so it doesn't pick an eye while moving or hits you, and also is the length that allows the slider part to have always full contact with the square rod. So, like I said before, file the tip, because metal can hurt. (It never ever happened to me and I do look at the printer like a mad men when printing to debug stuff).

Could I move the holder to the other corner?

Yes, print it mirroed (that's something I did ask at the beginning, but after using it on the Left side I would not change it, it just make's sense... Hard to explain..

Can I use a cheaper drivegear?

NO (well you actually could if you redesign most of the stuff, but if you just want to extrude without quality you can do it by hand )

Can I just print it on ABS or PLA, or China cheap PLA?

NO. ABS for example size changes a lot, it can't get as much flex torsion without deforming as platec/greentec. Ofc if you thing you can, just do it, but don't come here asking why it fails Also the material used must be as precise as possible, that something that only good brands give. You wan't to have as many things under- control as possible when printing printing this with a bowden since the tolerances are quite hard. Short answer, we recommend Greentec / Platec for hightemp and strength.

Could I avoid to print the Flexible material parts?

Oh yes, I forgot, there are parts that actually need to be printed on flexible materials like ninjaflex, recreus and a semiflex material. WHY? Just because (will explain all this on the video/tutorial). Most of them you can actually print them after installing the system, but also, well you can print them one by one very slow until you get the zge working

Why the motor holder moves a bit when printing?

Because the system compensates the extrusion forces to avoid as much motion transmission to the printhead. Also, better the motor holder than the printhead, right?

I have a dual printer, I wan't to use this!?

That's actually doable, Gudo even made a design that could work on a UM3. But... More or that someday. Basically we don't want to just make stuff that could work, but stuff that actually put something interesting on the table. There are many factors beyond making the extruder work on a um3 than just making it. Gudo actually I think did cover all of them, but then there's the part of the firmware. The UM3 firmware need's quite a lot knowhow to actually change parameters like Extrusion retraction while changing tools, prime amount, retraction amount, esteps, etc etc etc. So change this parameters on a um3 the user would need to know much knowhow to do stuff on linux without bricking the machine (editing stuff is really easy in the end but is a giant leap for most users). So for now we choose not to, but is there, if UM or maybe a modder makes a easy way to access the Machine Json files and edit them, then we might release it. Just because, it doesn't make sense to release stuff just for releasing stuff. Also, there's a big problemo for flexibles on um3, and that's the gap of air on top of the cores while they rest on the printhead.. So, could it work? Sure, but would it work everytime? That's the question... So, short answer, not yet.

More FAQ And important points about ZGE

Why we made it

Gudo and Neotko are moving forward this extruder because we are always pursuing quality, speed and precision. Bowden is a lightweight solution that creates quite a number of handicaps, like for example hysteresis (filament compression due pressure) making it impossible to actually control the extrusion. With ZGE Direct Drive this is now posible, for 1.75mm filaments and 2.85mm, without any compromise on Extrusion horse power.

Why don’t we sell it atm

Gudo and I (Neotko) have other interest than just selling upgrades. Is a nice idea, but we been crunching numbers and isn’t something we would love to be doing on the short time. I have a business and is starting to work and it demands my full time (except weekends where I try to keep improving every bit of the printer). Also isn’t that easy, to make a comercial version of the ZGE would requiere most probably a mold, and that’s freaking expensive, delivery, stock, gudo making sliders, me printing all the other parts, and that could be a nice dream but we don’t have a 100 printers farm to do it right, and sincerely is great to not need to defend something that you want to 'sell' it keeps the mind objective and fresh to new ideas.

So we have choose the YDIY (You Do It Yourself) path. I will make videos of how to print and assemble the key parts that requiere extreme love and care to do them right. Gudo I think can provide for some individuals the key parts, but don’t

overwhelm him, if you don’t get one, you need to DIY.

The good

It freaking works, it extrudes beautifully, it keeps working and working and delivering repetition and amazing precision even with flexibles. Bondtech dualdrive has a lot on that, it could be done with a lesser quality extruder gear, but it would give troubles, bondtech does work and work and work. It grinds a bit, NO, it pushes the filament over and over (and we get Zero commission from bondtech on this!). The system moves a 390mm square shaft of 4mm square. This was the first challenge. I have been testing a 3x3 thinner rod and it works beautifully, but it will only be of use for 1.75mm guys.

1.75mm requieres less heat to extrude, less pressure, but also it has a drawback, it need’s more rotation on the drive gear, this means more stuff moving. That’s why a 3x3mm is better, because it delivers less noise to the weak um head (more on that latter)

2.85mm requieres more heat to extrude, more pressure but also has the advantage of less rotation on the drivegear, this means less noise translated to the printhead, but more force. So for this the best is a 4x4 square shaft.

The Bad

The punny UM2 hotend. We are using a hotend designed specifically for bowden, and bowden has one advantage, remove pressure and movement on the printhead, that’s why any single force done on the printhead (even a wooble bowden shacking) can add noise to the prints. And for the ZGE this means that every rotation on the drivegear can, since the head has very easy to bend and flexible shafts, translate tinny bits on Z noise. Does this Z noise is perceptible? Well, is hard to see, but is there, most users that don’t have a perfect Z might not notice this, but since I’m a crazy guy I did noticed it. The first version was much more dependent of a perfect square shaft. Gudo made an amazing improvement to this problem developing a printable UJoint system that allows to remove the imperfections of a inexpensive rod (more on this later). And just yesterday, I got an idea (star medal for me on this since I’m really proud) we changed a part to be printed on flexible material removing almost 50% of the noise and making the prints look even better.

So... Does it print better than a Bowden? It freaking does. Does it has a bit more of noise on Z? Yes it does, sorry, that’s how things are. UM2 head, even the 8mm shafts can ‘bend’ and they keep wobbling making them very susceptible to Pressure from the drive-gears to the head. Every retract/extrude is a sudden move, that translates this sudden moves to the printhead. But with this last update the problem is hard to see, and most of normal users won’t ever see it.

The Ugly

To print a ZGE you need aprox 5h for the most delicate parts (slider+driveshaft) and they will need some post-processing. Add one hour of assembly for this part, that must be done with love and not by brute force. Also you do need a hightemperature

material, like greentec, platec. Just because this part get’s heat from the bed, so if you print at 60, the air will get there to 35C, and that + extrusion forces = bends. The Extruder head also should be greentec, platec. Is a very amazing material (we also get zero commission on this), but need’s hairspray on the bed and brims, and cleaning. I made a good article about how to add custom brims to the support, read it, read it again, and use it. You need all the parts to be printed perfect. More than 50mm/s can ruin the print and will add time to manual cleaning, that is less reliable than a 3dprinter.

You will need to calibrate your printer to the 0.02-0.03 closeness to the measures we will show as base. Just like Gudo and I did, we used one of the parts, print it and with a digital caliper of at least 2 decimal points, I did print the object 3 times, with different Horizontal Expansion values of -0.02 -0.03 -0.05. For me the winner was the 0.02. So as you can guess, the difference from printing it right or wrong is very very small. You need to keep that in mind for the main part of the ZGE, since is the most delicate part. First time I print one I did it horrible, and after printing 20-23 I thing I have enough practice to make a perfect ZGE slider+shaft.

The rest of the parts, need screws, nothing hard to find. There are two types of heads, one is more compact but need’s some special small 4mm mini shafts. The other, is more complex to assemble and is based on my Neotko-FatIRobertI extruder. Gudo also added a tension selector (very cool) to have 3 basic positions easy interchangeable. But is much complex to print. Also is taller... That... Well, shorter means less vibrations, taller more vibrations... Yea there are many many factors that we have take into account before posting this.

We still need to talk Gudo and I of what basic version we release. Most probably the slider, they key part, won’t have a step file release, but the others might, or not. The important is that all the parts will be easy to print, except the slider (the slider, as I said over and over here must be printed with love and finished more or less by hand).

The Main key parts you will need to get to DIY.

First of all, the square rod of 390mm, there are shops on ebay that cut on demand, but try to be ware that the tip you need to soft it (file it) for safety! You don’t want to loose an eye because you didn’t hear us out right?

For precision square shafts (they call them Key Steel or Parallel Key) the max length we where able to find is 350mm (on misumi) so that means that it would not work. It need’s to be a minimum of 390mm. Gudo might be able to provide this to some users, but again, ask once, if he doesn’t answer he is busy doing something more interesting, don’t hammer it. And you will need to pay for it, you know, square shafts don’t grow on trees.

A shorter smaller screw. You know the four screws that hold your hotend? Well, one must be shorter, like 4mm taller, you can ‘sew’ it yourself indeed. Again, not easy to find. Gudo is amazing and he made me a few with the first kits he made for me.

Bondtech Drive gears for 1.75 or 2.85 you need the 8mm shaft dia, with 4mm -

24-25mm long shaft for the mirror gear.

Motor. I have use, and I keep using, the UMO motor without any geared solution. For 1.75 works perfectly. For 2.85 the best (until one of the beta testers install it and test the motor I sent) is a Bondtech 5.18 geared nema. It works and works.

I have a shop, I want to sell it!

Contact Gudo for this, you two might get along and do some business. I personally would love to see this extruder on every printer out there. But mind one thing, no shortcuts, no china quality. If you thing you are decent, come talk with Gudo.

I want it for my printer!

Our dream is to have this on as many printers as possible, a Bowden-free world. If you are a 3d printer maker contact us and we will study making a version of our ZGE for your machine. But remember this is Open Source, so we will focus on Open Source machines like UM, BCN, and probably others.

If we don’t support your printer, give us time, we are just two guys that love 3d printing and making our printers as precise as possible. Contact your printer company, if they give us access to your files we might do it! And ofc if you have a Solid Robust No Woobly printer, we are interested But ofc, Maybe Gudo just make's a better printer out of this UM.... But that's a history for other day

3d model print parameters

ZGE BOM LIST- BONDTECH Dual Gears kit 1.75mm or 2.85mm/shaft dia 8mm

* important if use

Iroberti order the 4mm x 22mm driven gear pin

Short ZG...E order the 4mm x 25mm driven gear pin

- 4x4mm precision Square Rod - Steel or Stainless steel - 390/400 mm lenght

- ZGE Bearings

8x - 3x8x3 ZZ (slider)

2x - 8x16x5 ZZ (extruder)

2x - 10x19x5 ZZ (frame motor holder)

2x - 12x21x5 ZZ (print head extruder holder)

- Fastener metric M3 SOCKET HEAD BOLTS & NUTS

- ADJUSTABLE FRAME MOTOR HOLDER

2x 20mm (UM2 frame)

2x 18mm (UMO frame)

2x 8mm + nut

1x 35mm + nut

- MOTOR SHAFT/SQUARE ROD COUPLER

4x 12mm + M3 nut

- STEPPER MOTOR HOLDER

4x 10mm

3x 16mm + nut

- SLIDER

10x 18mm + nut

- GEAR DRIVE SHAFT

2x 18mm + nut

- EXTRUDER

- IRoberti version

* 3x 8mm Hexagon socket button head (or Philips equivalent)

3x 30mm + nut

- SHORT version

* 4x 8mm Hexagon socket button head (or Philips equivalent)

1x 30mm + nut

- SPRING SREW for the 2 Extruder versions

1x 35/40 mm HEXAGONAL head + nut

- Short ZGE Spring pressure guide

2x 4mm x 18mm pin