Fab lab tulsa trophy 3D for print

12018 Views 2 Likes 0 Downloads Download the piece here from 3dforprint

https://youtu.be/s-bARRh3fmM

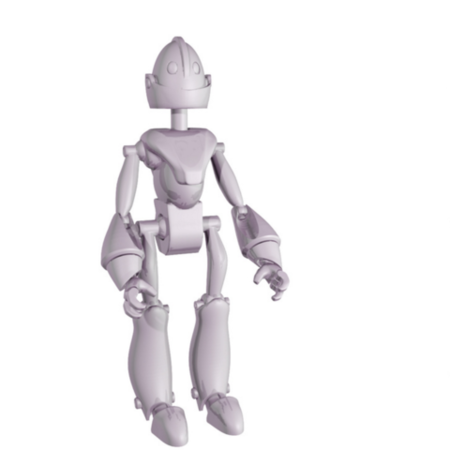

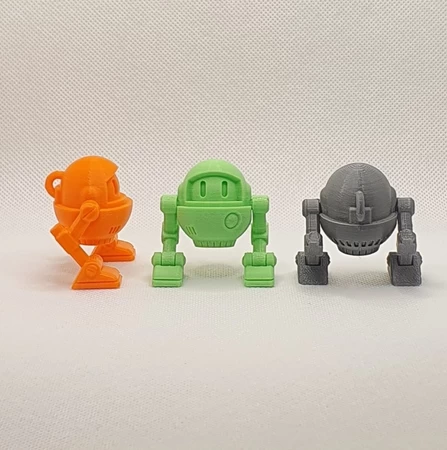

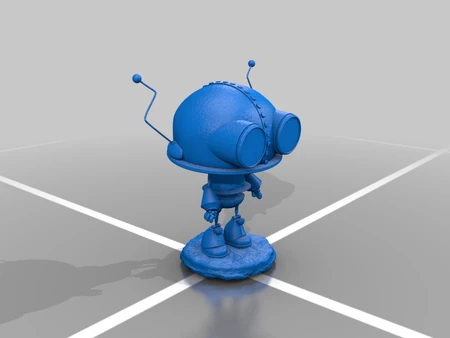

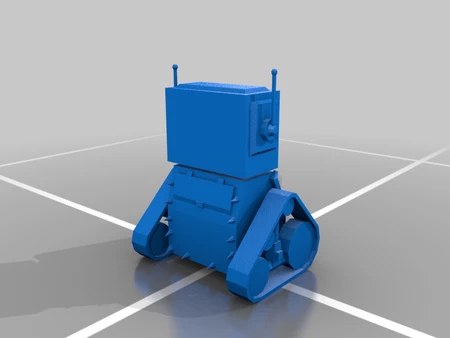

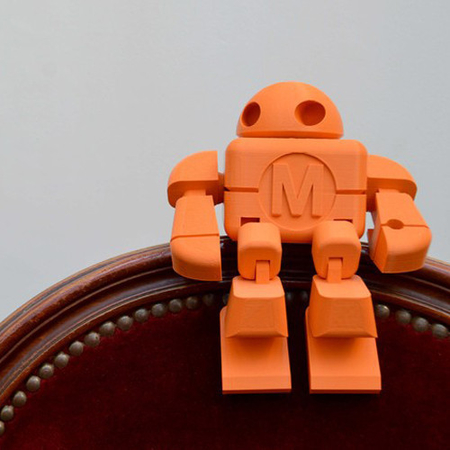

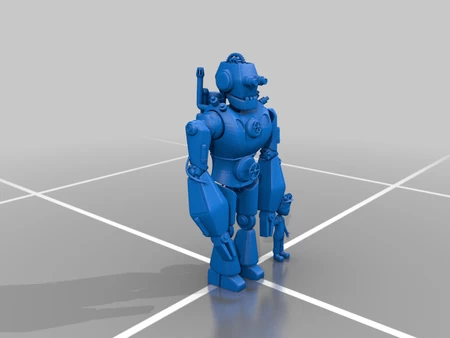

Fab Lab Tulsa invited our family to be their guests at Tulsa Maker Faire 2019, and of course... we gladly accepted. At the end of our day at the event, we purchased t-shirts and very cute small windup "dancing" robots for the entire family. "Fab Lab Tulsa Trophy" is a larger, less complicated, motorized version of the windup dancing robots that I designed, 3D printed and assembled to thank Fab Lab Tulsa for their hospitality and to celebrate their success with Tulsa Maker Faire 2019.

With the first trophy completed, everyone who saw it smiled. So I updated the design for family and friends to include animated gear fronts and customized / customizable medallions. I've included the file "Medallion, Blank.stl" to which a 2D printed sticker may be applied for customizing the trophy.

As usual, I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to ask as I do make plenty of mistakes.

Designed using Autodesk Fusion 360, sliced using Cura 4.2, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker 3 Extended.

I purchased the following parts:

• 150rpm 6VDC Gear Motor (search for "DC 6V 150RPM Micro Speed Reducti...on Motor Electric Geared Motor").

• One 1.5, 3, 4.5, 5VDC variable power adapter (available online).

The included file "Parts.pdf" contains the part names, quantities, layer heights, infill and support settings of the parts I 3D printed for this model. The file "Medallion, Blank.stl" contains a blank medallion to which a 2D printed sticker may be applied for customization. The ".3mf" files are for the dual extrusion head and medallions.

This is a high precision print and assembly model. Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on you printer, your printer settings and the colors you chose, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely sure that all build plate "ooze" is removed and that all edges are smooth. I used small jewelers files and plenty of patience to perform this step.

The model also uses threaded assembly, so I used a tap and die set (6mm by 1, 8mm by 1.25) for thread cleaning.

I used small dots of cyanoacrylate glue to secure threads if needed, and light machine oil for lubrication of the gears and axles.

Assemble the Body.

To assemble the body, I performed the following steps:

• Pressed the motor into "Body, Rear.stl" until the motor shaft extended 3mm above the motor gear plate.

• Soldered 120mm lengths of red and black wires to the motor "+" and "-" terminals respectively, then used a small dot of thick cyanoacrylate glue to attach the wires to the body for strain relief.

• Pressed "Neck.stl" into the body assembly.

• Pressed "Gear, Crown, Motor.stl" onto the motor shaft.

• Positioned "Gear, Crown, Axle.stl" on the body assembly, pressed "Axle, Cam.stl" through the crown gear and the rear of the body assembly, then threaded "Cam.stl" onto the axle assembly making sure not to over-tighten.

• Positioned "Body, Front.stl" onto the body assembly and secured in place with two "Bolt, Front.stl".

Assemble and Attach the Legs.

To assemble and attach the legs, I performed the following steps:

• Threaded one "Pin, Leg.stl" into "Leg, Left.stl".

• Threaded the motor wires down the the left leg assembly and out through the foot.

• Attached the left leg assembly to the body assembly using one "Axle, Leg.stl" making sure not to over-tighten the axle.

• Threaded the remaining "Pin, Leg.stl" into "Leg, Right.stl".

• Attached the right leg assembly to the body assembly using one "Axle, Leg.stl" making sure not to over-tighten the axle.

• Made sure both leg assemblies rotated with ease.

Assemble and Attach the Arms.

To assemble and attach the arms, I performed the following steps:

• Positioned "Arm, Left,Lower.stl" over "Arm, Left, Upper.stl" and secured in place using one "Bolt, Arms.stl", making sure not to over-tighten the bolt.

• Positioned "Arm, Swing.stl" over the arm assembly and secured in place using one "Bolt, Arms.stl", making sure not to over-tighten the bolt.

• Attached the free end of arm swing to the body using one "Bolt, Shoulder, Long.stl", making sure not to over-tighten the bolt.

• Attached the free end of the upper arm to the body using one "Bolt, Shoulder, Short.stl", making sure not to over-tighten the bolt.

• Repeated these steps for the right arm.

• Made sure both arm assemblies rotated with ease.

Attach the Head.

To attach the head, I performed the following steps:

• Pressed "Arm, Head.stl" onto "Axle, Neck.stl".

• Positioned "Head.3mf" on the neck, then threaded the axle assembly through the head and neck until snug and the arm is positioned straight downward.

• Made sure the head assembly rotated freely.

Final Assembly.

For final assembly, I performed the following steps:

• Positioned "Control Plate.stl" onto the body assembly such that both upper arm pins, both leg pins and the head pin were located in the control plate slots.

• Threaded "Axle, Control Plate.stl" through the hole in the control plate and into the body assembly, making sure not to over-tighten the axle and that the axle rotated freely.

• Threaded "Axle, Cam.stl" through the slot in the control plate and into the cam, making sure not to over-tighten the axle.

• Threaded the medallion onto the cam axle, making sure not to over-tighten the medallion.

• Soldered the power adapter wires to the red and black motor wires, then secured the extra length of wire inside the left foot using small dots of cyanoacrylate glue.

With final assembly complete, I placed small dots of light machine oil on the gears and axles, set the power supply to 1.5VDC and plugged it in. Using an ammeter, I measured the current draw of each model and found it to be between 12 and 20ma.

And that is how I 3D printed and assembled Fab Lab Tulsa Trophy.

I hope you enjoyed it!

Designer

Greg Zumwalt3d model description

A trophy for Fab Lab Tulsahttps://youtu.be/s-bARRh3fmM

Fab Lab Tulsa invited our family to be their guests at Tulsa Maker Faire 2019, and of course... we gladly accepted. At the end of our day at the event, we purchased t-shirts and very cute small windup "dancing" robots for the entire family. "Fab Lab Tulsa Trophy" is a larger, less complicated, motorized version of the windup dancing robots that I designed, 3D printed and assembled to thank Fab Lab Tulsa for their hospitality and to celebrate their success with Tulsa Maker Faire 2019.

With the first trophy completed, everyone who saw it smiled. So I updated the design for family and friends to include animated gear fronts and customized / customizable medallions. I've included the file "Medallion, Blank.stl" to which a 2D printed sticker may be applied for customizing the trophy.

As usual, I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to ask as I do make plenty of mistakes.

Designed using Autodesk Fusion 360, sliced using Cura 4.2, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker 3 Extended.

3d model print parameters

Purchase, Print and Prepare the Parts.I purchased the following parts:

• 150rpm 6VDC Gear Motor (search for "DC 6V 150RPM Micro Speed Reducti...on Motor Electric Geared Motor").

• One 1.5, 3, 4.5, 5VDC variable power adapter (available online).

The included file "Parts.pdf" contains the part names, quantities, layer heights, infill and support settings of the parts I 3D printed for this model. The file "Medallion, Blank.stl" contains a blank medallion to which a 2D printed sticker may be applied for customization. The ".3mf" files are for the dual extrusion head and medallions.

This is a high precision print and assembly model. Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on you printer, your printer settings and the colors you chose, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely sure that all build plate "ooze" is removed and that all edges are smooth. I used small jewelers files and plenty of patience to perform this step.

The model also uses threaded assembly, so I used a tap and die set (6mm by 1, 8mm by 1.25) for thread cleaning.

I used small dots of cyanoacrylate glue to secure threads if needed, and light machine oil for lubrication of the gears and axles.

Assemble the Body.

To assemble the body, I performed the following steps:

• Pressed the motor into "Body, Rear.stl" until the motor shaft extended 3mm above the motor gear plate.

• Soldered 120mm lengths of red and black wires to the motor "+" and "-" terminals respectively, then used a small dot of thick cyanoacrylate glue to attach the wires to the body for strain relief.

• Pressed "Neck.stl" into the body assembly.

• Pressed "Gear, Crown, Motor.stl" onto the motor shaft.

• Positioned "Gear, Crown, Axle.stl" on the body assembly, pressed "Axle, Cam.stl" through the crown gear and the rear of the body assembly, then threaded "Cam.stl" onto the axle assembly making sure not to over-tighten.

• Positioned "Body, Front.stl" onto the body assembly and secured in place with two "Bolt, Front.stl".

Assemble and Attach the Legs.

To assemble and attach the legs, I performed the following steps:

• Threaded one "Pin, Leg.stl" into "Leg, Left.stl".

• Threaded the motor wires down the the left leg assembly and out through the foot.

• Attached the left leg assembly to the body assembly using one "Axle, Leg.stl" making sure not to over-tighten the axle.

• Threaded the remaining "Pin, Leg.stl" into "Leg, Right.stl".

• Attached the right leg assembly to the body assembly using one "Axle, Leg.stl" making sure not to over-tighten the axle.

• Made sure both leg assemblies rotated with ease.

Assemble and Attach the Arms.

To assemble and attach the arms, I performed the following steps:

• Positioned "Arm, Left,Lower.stl" over "Arm, Left, Upper.stl" and secured in place using one "Bolt, Arms.stl", making sure not to over-tighten the bolt.

• Positioned "Arm, Swing.stl" over the arm assembly and secured in place using one "Bolt, Arms.stl", making sure not to over-tighten the bolt.

• Attached the free end of arm swing to the body using one "Bolt, Shoulder, Long.stl", making sure not to over-tighten the bolt.

• Attached the free end of the upper arm to the body using one "Bolt, Shoulder, Short.stl", making sure not to over-tighten the bolt.

• Repeated these steps for the right arm.

• Made sure both arm assemblies rotated with ease.

Attach the Head.

To attach the head, I performed the following steps:

• Pressed "Arm, Head.stl" onto "Axle, Neck.stl".

• Positioned "Head.3mf" on the neck, then threaded the axle assembly through the head and neck until snug and the arm is positioned straight downward.

• Made sure the head assembly rotated freely.

Final Assembly.

For final assembly, I performed the following steps:

• Positioned "Control Plate.stl" onto the body assembly such that both upper arm pins, both leg pins and the head pin were located in the control plate slots.

• Threaded "Axle, Control Plate.stl" through the hole in the control plate and into the body assembly, making sure not to over-tighten the axle and that the axle rotated freely.

• Threaded "Axle, Cam.stl" through the slot in the control plate and into the cam, making sure not to over-tighten the axle.

• Threaded the medallion onto the cam axle, making sure not to over-tighten the medallion.

• Soldered the power adapter wires to the red and black motor wires, then secured the extra length of wire inside the left foot using small dots of cyanoacrylate glue.

With final assembly complete, I placed small dots of light machine oil on the gears and axles, set the power supply to 1.5VDC and plugged it in. Using an ammeter, I measured the current draw of each model and found it to be between 12 and 20ma.

And that is how I 3D printed and assembled Fab Lab Tulsa Trophy.

I hope you enjoyed it!