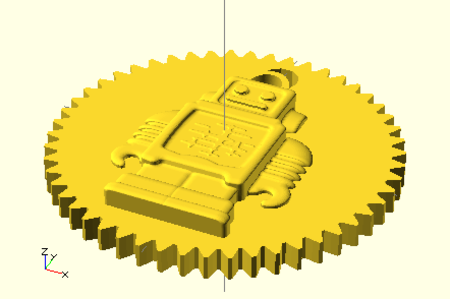

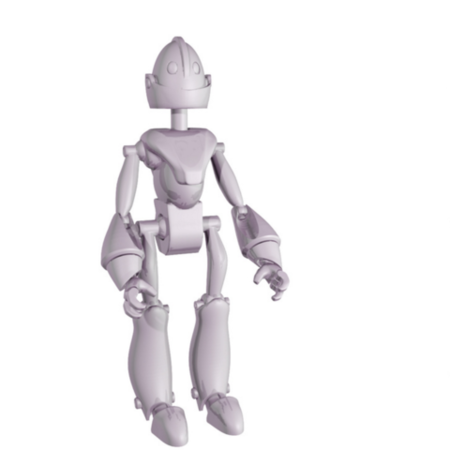

Ultimaker robot "pin walker". 3D for print

6935 Views 2 Likes 0 Downloads Download the piece here from 3dforprint

A Youtube follower suggested that I design a "pin walker" mechanism, which I had never seen nor heard of, s...o he directed me to the RobotHut website and I was so intrigued that I immediately begin designing a pin walker mechanism. After designing the mechanism, since I use Ultimaker 3D printers I decided to complete the model using the Ultimaker Robot as the body for Ultimaker Robot "Pin Walker".

As usual, I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to ask as I do make plenty of mistakes.

Designed using Autodesk Fusion 360, sliced using Cura 4.2, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker 3 Extended.

One final note, I receive no compensation in any form for the parts and/or materials used in this model.

Purchase, Print and Prepare the Parts.>/b>

I used the following supplies:

• Thick cyanoacrylate glue.

• Cyanoacrylate glue accelerant.

• Light machine oil.

• Solder.

• Double sided tape.

This model uses the following non-3D printed parts:

• One 3.7vdc 100ma Lithium Battery (https://www.adafruit.com/product/1570).

• One JST PH 2-Pin Cable (https://www.adafruit.com/product/3814).

• One N20 6VDC 150RPM gear motor.

• One micro switch (Uxcell a12013100ux0116 High Knob 3P 2 Position 1P2T SPDT Vertical Slide Switch, 0.5 Amp, 50V DC, 50 Piece, 3 mm).

You will also need a suitable battery charger.

For the 3D printed parts, I've included the file "3D Printed Parts.pdf" containing the part names, count, layer height, infill and support settings for the 3D parts I printed.

This is a high precision print and assembly model using at times very small parts and in very tight spaces. Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on you printer, your printer settings and the colors you chose, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely certain that all build plate "ooze" is removed and that all edges are smooth. I used small jewelers files and plenty of patience to perform this step.

The model also uses threaded assembly, so I used a tap and die set (6mm by 1) for thread cleaning.

I used a small dot of thick cyanoacrylate glue to attach the the body rear section to the body front section, secure the wiring to the base and to secure threads if needed.

I also used light machine oil for lubrication of the gears and axles.

To wire the robot motor and on/off switch, I performed the following steps:

• Cut the wires on the JST... connector to 40mm in length, then stripped and tinned the ends.

• Soldered the black wire from the JST connector to the motor "-" terminal.

• Soldered the red wire from the JST connector to one of the outside switch terminal.

• Soldered a red wire from the center pin of the switch to the motor "+" terminal.

After wiring, I connected the JST connector the battery and operated the switch to turn the motor on and off.

Assemble the Base.

To assemble the base, I performed the following steps:

• Pressed the gear motor into "Base.stl" such that the motor shaft was 3mm above the motor gear plate.

• Pressed "Gear, Crown, Motor.stl" onto the motor shaft.

• Positioned "Gear, Crown, Axle.stl" inside the base assembly over the smaller axle hole.

• Slid the longer hexagonal shaft of "Axle.stl" into the base assembly larger axle hole.

• Pressed the longer hexagonal axle shaft through the axle gear and out the smaller axle hole in the base assembly.

• Pressed one "Cam.stl" onto the axle and rotated the gear train such that the cam was at its upper most position.

• Pressed the remaining "Cam.stl" onto the other end of the axle such that the cam was at its lower most position (180 degrees from the first cam).

• Slid one "Leg.stl" into the base assembly and positioned the cam ring over the cam, then secured in place with one "Axle, Leg.stl".

• Slid the remaining "Leg.stl" into the base assembly and positioned the cam ring over the cam, then secured in place with the remaining "Axle, Leg.stl".

• Positioned "Seesaw.stl" over the upper threaded hole on the base assembly then secured in place with "Axle, Seesaw.stl".

• Pressed the battery connector between the robot foot and motor housing on the base assembly then secured the battery to the base assembly using double sided tape.

At this point, I connected the motor to a power supply in order to test the assembly. I lubricated and operated the assembly and noted the power consumption to be 18 to 20ma.

Final Assembly.

For final assembly, I performed the following steps:

• Rotated the gear train until the seesaw was horizontal.

• Positioned "Ultimaker Robot, Front.stl" (or "Ultimaker Robot, Front.3mf") over the lower threaded hole on the front of the base assembly, making sure the gear teeth on the robot front engaged with the gear teeth on the seesaw, then secured in place with one "Axle, Body.stl".

• Positioned "Ultimaker Robot, Rear.stl" over the lower threaded hole on the rear of the base assembly then secured in place with the remaining "Axle, Body.stl".

• Secured the body halves together using either one small dot of cyanoacrylate glue or small strips of double sided tape.

• Secured the switch to the inside of the foot using either one small dot of cyanoacrylate glue or a small strip of double sided tape.

And that is how I printed and assembled Ultimaker Robot "Pin Walker".

I hope you enjoyed it!

Designer

Greg Zumwalt3d model description

The Ultimaker Robot in "Pin Walker" form.A Youtube follower suggested that I design a "pin walker" mechanism, which I had never seen nor heard of, s...o he directed me to the RobotHut website and I was so intrigued that I immediately begin designing a pin walker mechanism. After designing the mechanism, since I use Ultimaker 3D printers I decided to complete the model using the Ultimaker Robot as the body for Ultimaker Robot "Pin Walker".

As usual, I probably forgot a file or two or who knows what else, so if you have any questions, please do not hesitate to ask as I do make plenty of mistakes.

Designed using Autodesk Fusion 360, sliced using Cura 4.2, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker 3 Extended.

One final note, I receive no compensation in any form for the parts and/or materials used in this model.

Purchase, Print and Prepare the Parts.>/b>

I used the following supplies:

• Thick cyanoacrylate glue.

• Cyanoacrylate glue accelerant.

• Light machine oil.

• Solder.

• Double sided tape.

This model uses the following non-3D printed parts:

• One 3.7vdc 100ma Lithium Battery (https://www.adafruit.com/product/1570).

• One JST PH 2-Pin Cable (https://www.adafruit.com/product/3814).

• One N20 6VDC 150RPM gear motor.

• One micro switch (Uxcell a12013100ux0116 High Knob 3P 2 Position 1P2T SPDT Vertical Slide Switch, 0.5 Amp, 50V DC, 50 Piece, 3 mm).

You will also need a suitable battery charger.

For the 3D printed parts, I've included the file "3D Printed Parts.pdf" containing the part names, count, layer height, infill and support settings for the 3D parts I printed.

This is a high precision print and assembly model using at times very small parts and in very tight spaces. Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on you printer, your printer settings and the colors you chose, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely certain that all build plate "ooze" is removed and that all edges are smooth. I used small jewelers files and plenty of patience to perform this step.

The model also uses threaded assembly, so I used a tap and die set (6mm by 1) for thread cleaning.

I used a small dot of thick cyanoacrylate glue to attach the the body rear section to the body front section, secure the wiring to the base and to secure threads if needed.

I also used light machine oil for lubrication of the gears and axles.

3d model print parameters

Wire the Robot Motor and On/Off Switch.To wire the robot motor and on/off switch, I performed the following steps:

• Cut the wires on the JST... connector to 40mm in length, then stripped and tinned the ends.

• Soldered the black wire from the JST connector to the motor "-" terminal.

• Soldered the red wire from the JST connector to one of the outside switch terminal.

• Soldered a red wire from the center pin of the switch to the motor "+" terminal.

After wiring, I connected the JST connector the battery and operated the switch to turn the motor on and off.

Assemble the Base.

To assemble the base, I performed the following steps:

• Pressed the gear motor into "Base.stl" such that the motor shaft was 3mm above the motor gear plate.

• Pressed "Gear, Crown, Motor.stl" onto the motor shaft.

• Positioned "Gear, Crown, Axle.stl" inside the base assembly over the smaller axle hole.

• Slid the longer hexagonal shaft of "Axle.stl" into the base assembly larger axle hole.

• Pressed the longer hexagonal axle shaft through the axle gear and out the smaller axle hole in the base assembly.

• Pressed one "Cam.stl" onto the axle and rotated the gear train such that the cam was at its upper most position.

• Pressed the remaining "Cam.stl" onto the other end of the axle such that the cam was at its lower most position (180 degrees from the first cam).

• Slid one "Leg.stl" into the base assembly and positioned the cam ring over the cam, then secured in place with one "Axle, Leg.stl".

• Slid the remaining "Leg.stl" into the base assembly and positioned the cam ring over the cam, then secured in place with the remaining "Axle, Leg.stl".

• Positioned "Seesaw.stl" over the upper threaded hole on the base assembly then secured in place with "Axle, Seesaw.stl".

• Pressed the battery connector between the robot foot and motor housing on the base assembly then secured the battery to the base assembly using double sided tape.

At this point, I connected the motor to a power supply in order to test the assembly. I lubricated and operated the assembly and noted the power consumption to be 18 to 20ma.

Final Assembly.

For final assembly, I performed the following steps:

• Rotated the gear train until the seesaw was horizontal.

• Positioned "Ultimaker Robot, Front.stl" (or "Ultimaker Robot, Front.3mf") over the lower threaded hole on the front of the base assembly, making sure the gear teeth on the robot front engaged with the gear teeth on the seesaw, then secured in place with one "Axle, Body.stl".

• Positioned "Ultimaker Robot, Rear.stl" over the lower threaded hole on the rear of the base assembly then secured in place with the remaining "Axle, Body.stl".

• Secured the body halves together using either one small dot of cyanoacrylate glue or small strips of double sided tape.

• Secured the switch to the inside of the foot using either one small dot of cyanoacrylate glue or a small strip of double sided tape.

And that is how I printed and assembled Ultimaker Robot "Pin Walker".

I hope you enjoyed it!