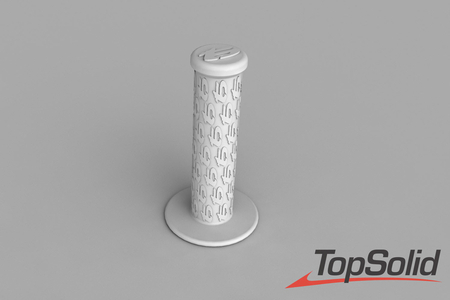

Ultimaker 2 straight tube flexible filament spool holder 3D for print

17286 Views 2 Likes 0 Downloads Download the piece here from 3dforprint

With this little tower you will straighten and make shorter the bowden tube. This will highl...y improve print quality of flexible materials (see attached photo of Semiflex filament).

Note that you will have to print Hinge.stl and FlexConnector.stl from flexible material. It still works like a charm (and did not break in the months I used it), so it is time to share. Models of my CAD program (ZW3D) are included in the 7-Zip file.

Achieved results: Printing NinjaFlex and Semiflex in layers of 0.1mm thickness without problems. Printspeed as with normal materials. Retraction still did not work.

Some ideas behind the design:

- Makes it possible to print flexible materials, but still with a lightweight printhead (allowing fast movement)

- The springs on the back will lift the heavy extruder-motor, and act more or less as a kind of gravity compensation.

- As the tower is part of the printer, it keeps the printer relative portable

- Spool holder is oriented such that the filament bends in the direction how it goes through the tube, instead of making a 90deg twist like in the original setup. This prevents additional stresses to build up in the tube/guide.

- When mirrored, two towers can be mounted; dual head compatible.

- Spool holder shaft can be easily taken out of the tower (complete with spool, bearings and 'Spool Holder Centerring'), this makes it possible to easily exchange spool from front of the machine, even when two spools are mounted.

- Filament spool holder has been improved (using bearings for smooth roll-off, using bearings to guide the filament into the extruder)

- Any extruder should work, you can use IRobertI's Alternative feeder V2 (https://www.youmagine.com/designs/alternative-um2-feeder-version-two).

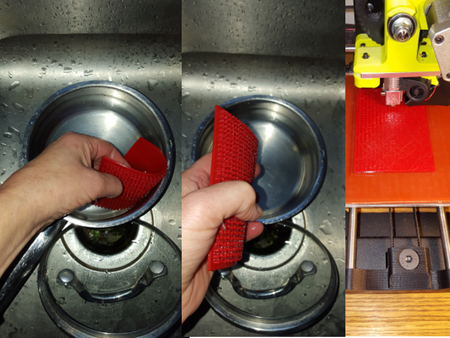

Note 1: you should break the guidance for the filament, because the axis of the motor and the small bearings that guide the filament in the extruder will conflict with it. See photo "Extruder.png".

Note 2: You should also add the small modification in order to be able to print flexible material. You can find it here: https://www.youmagine.com/designs/feeder-bearing-mod-for-flexible-filament

- Note 3: As the extruder is still about 20cm away from the nozzle, retraction still does not work (as far as I have tested).

- Note 4: As I am a little lazy, till now I did not try to align the feeder parameters. I just manually insert the filament, and then set manually the material type by selecting it via the settings in the ultimaker display menus. Don't know if we can tweak the auto-feeder distance, I would expect a parameter in the machine parameters of Cura.

- 4x RS 821-396 spring (http://nl.rs-online.com/web/p/extension-springs/0821396)

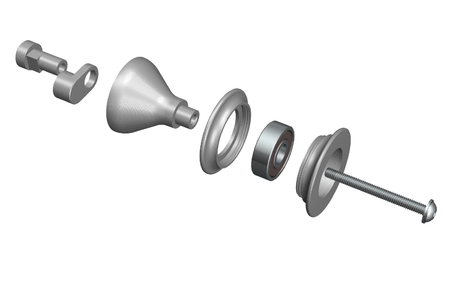

- 2x RS ball bearing 619-02...88 (http://nl.rs-online.com/web/p/ball-bearings/6190288/?searchTerm=619-0288)

- 3x RS ball bearing 893-7420 (http://nl.rs-online.com/web/p/ball-bearings/8937420/?searchTerm=893-7420) (-> Note: these bearings might not be required! I have been printing for a while now without and that seems to work better than with bearings, as sometimes the filament gets stuck in the gap between bearings.)

- Some M3 bolts & nuts (note that you can re-use the bolts of the existing extruder for fixation of the tower to the printer, for mounting the extruder and springs you will need new bolts)

- Some wire&shrink sleeves to extend the wire of the extruder motor

Designer

antonverburg3d model description

Ultimaker 2 Straight tube flexible filament spool holderWith this little tower you will straighten and make shorter the bowden tube. This will highl...y improve print quality of flexible materials (see attached photo of Semiflex filament).

Note that you will have to print Hinge.stl and FlexConnector.stl from flexible material. It still works like a charm (and did not break in the months I used it), so it is time to share. Models of my CAD program (ZW3D) are included in the 7-Zip file.

Achieved results: Printing NinjaFlex and Semiflex in layers of 0.1mm thickness without problems. Printspeed as with normal materials. Retraction still did not work.

Some ideas behind the design:

- Makes it possible to print flexible materials, but still with a lightweight printhead (allowing fast movement)

- The springs on the back will lift the heavy extruder-motor, and act more or less as a kind of gravity compensation.

- As the tower is part of the printer, it keeps the printer relative portable

- Spool holder is oriented such that the filament bends in the direction how it goes through the tube, instead of making a 90deg twist like in the original setup. This prevents additional stresses to build up in the tube/guide.

- When mirrored, two towers can be mounted; dual head compatible.

- Spool holder shaft can be easily taken out of the tower (complete with spool, bearings and 'Spool Holder Centerring'), this makes it possible to easily exchange spool from front of the machine, even when two spools are mounted.

- Filament spool holder has been improved (using bearings for smooth roll-off, using bearings to guide the filament into the extruder)

- Any extruder should work, you can use IRobertI's Alternative feeder V2 (https://www.youmagine.com/designs/alternative-um2-feeder-version-two).

Note 1: you should break the guidance for the filament, because the axis of the motor and the small bearings that guide the filament in the extruder will conflict with it. See photo "Extruder.png".

Note 2: You should also add the small modification in order to be able to print flexible material. You can find it here: https://www.youmagine.com/designs/feeder-bearing-mod-for-flexible-filament

- Note 3: As the extruder is still about 20cm away from the nozzle, retraction still does not work (as far as I have tested).

- Note 4: As I am a little lazy, till now I did not try to align the feeder parameters. I just manually insert the filament, and then set manually the material type by selecting it via the settings in the ultimaker display menus. Don't know if we can tweak the auto-feeder distance, I would expect a parameter in the machine parameters of Cura.

3d model print parameters

- Printed parts (as shown in STL files)- 4x RS 821-396 spring (http://nl.rs-online.com/web/p/extension-springs/0821396)

- 2x RS ball bearing 619-02...88 (http://nl.rs-online.com/web/p/ball-bearings/6190288/?searchTerm=619-0288)

- 3x RS ball bearing 893-7420 (http://nl.rs-online.com/web/p/ball-bearings/8937420/?searchTerm=893-7420) (-> Note: these bearings might not be required! I have been printing for a while now without and that seems to work better than with bearings, as sometimes the filament gets stuck in the gap between bearings.)

- Some M3 bolts & nuts (note that you can re-use the bolts of the existing extruder for fixation of the tower to the printer, for mounting the extruder and springs you will need new bolts)

- Some wire&shrink sleeves to extend the wire of the extruder motor