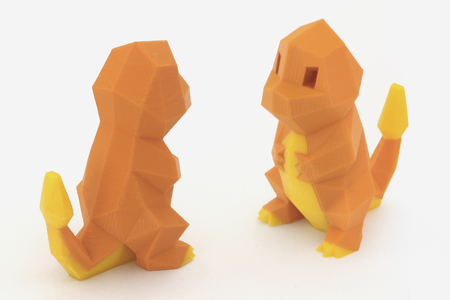

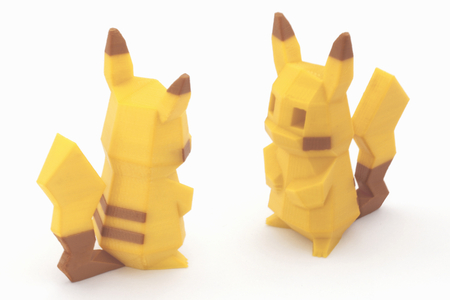

Prusa compacto extrusora de renovación en 3D para imprimir

4237 Visualizaciones 2 Me gusta 0 Descargas realizadas Descarga aqui la pieza desde 3dforprint

Mi impresora es una Prusa i3 cuadro-marco. Sin embargo, las piezas impresas compré para hacer (mi primera impresora) incluido el x carro y Camina extrusora de aquí: http://www.thingiverse.com/thing:119616.

Yo estaba bastante contento con esta configuración hasta que me di cuenta de que la boquilla fue más de 0,1 mm más cerca de la cama cuando se encuentra en la x centro de la cama que estaba en el x bordes de la cama, haciendo el transporte subterráneo para más de 0.1 mm imposible. Finalmente, después de probar muchas cosas, he determinado que la causa de este problema fue el flex en la (8 mm) x varillas combinado con el centro de masa de la pesada Vadea el extrusor de estar bien delante de la x varillas y la boquilla también de estar bien delante de la x varillas.

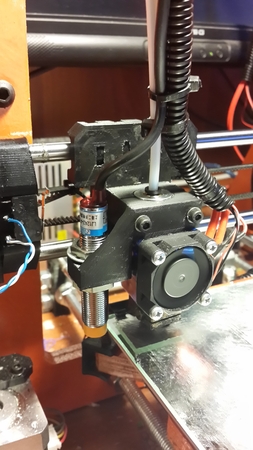

Como resultado, decidí imprimir un nuevo extrusor y el monte que mover la boquilla tan cerca como sea posible a la parte inferior de x de la varilla y también mover el centro de masa más cerca de la x varillas.

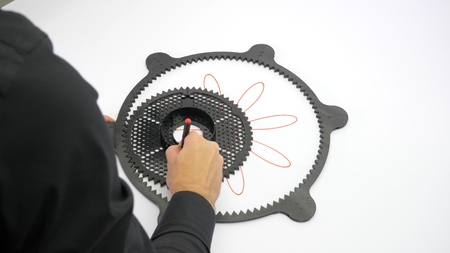

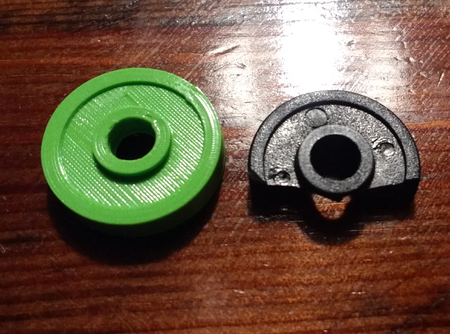

Yo uso 3 mm de filamento y también me gusta usar un poquito de peso (250 g) paso a paso sobre la (no-Bowden) extrusora para mantener el x transporte total de la masa hacia abajo, por lo que necesito un razonablemente grandes, la relación de engranajes (1:4) y un Mk8 hobbed equipo suficiente par. Prusa compacto del extrusor de la prusa-vainilla repo me parecía simple y luz (M5 varilla y 625ZZ rodamientos) aparte de necesitar un gran paso a paso, así que me rediseñado para el uso de un 8 a 32 relación de transmisión (desde el 8 al 24). Para mover el centro de masa lo más cerca posible a la x varillas he planteado el motor, de manera que se podría extender a través de la parte superior de la x carro.

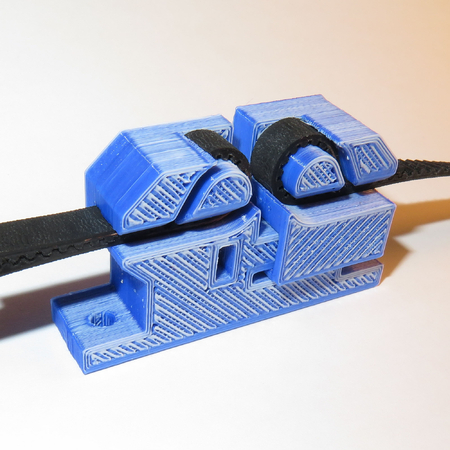

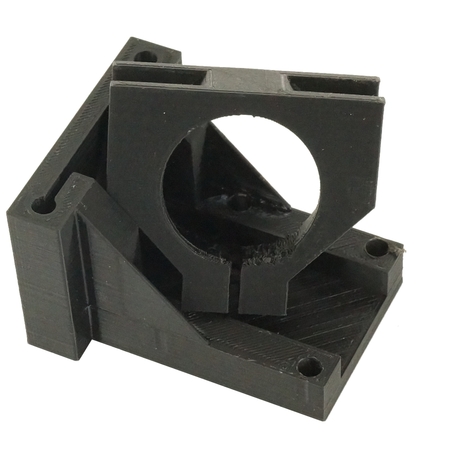

Yo no quería cambiar la x carro porque es muy suave, con no decantación, así que he diseñado un monte ( basado en http://www.thingiverse.com/thing:148536) para conectar mi E3D v6 directamente al carro tan alto como sea posible, y un offset para mantener el centro de masa cerca del centro de el carro en la dirección x. Entonces me tornillo de la extrusora a este monte el uso normal de 50 mm espaciados groovemount agujeros en la extrusora.

Tenga en cuenta que uno de los M4 tornillos utilizados para fijar la montura para el transporte también se utiliza para mantener el hot-end en el lugar.

Ahora puedo tranvía con precisión a través de toda la

200x200 placa de construcción.

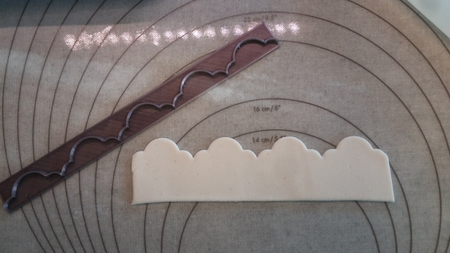

Puedo imprimir estas piezas con Kisslicer medio de soporte (ABS).

El soporte está diseñado para ser un ajuste apretado en un E3Dv6 y es, probablemente, demasiado apretado para un E3Dv5, para que el extruder_cyl2_height parámetro debe ser reducida. La montura debe estar impreso con un 0,2 mm de altura de capa.

Yo uso una 0.26 altura de capa para el extrusor y la polea.

Cuando el montaje de la extrusora, no apriete las tuercas a cada lado de la frente-la mayoría de rodamiento contra el cojinete. Esto es debido a que el rodamiento de IDENTIFICACIÓN será un poco más grande que el diámetro del eje, por lo que las posibilidades son de que el rodamiento no se centra exactamente en el eje, causando que el eje se mueva a medida que gira. Es mejor dejar que el rodamiento delantero un poco floja, como la espalda, uno tiene que ser. Yo pack el eje donde el hobbed es un engranaje con un par de capas de papel de aluminio antes de montar el engranaje, hacia el centro.

Las fuentes también disponible aquí: https://github.com/spinorkit/Prusa3-vanilla

- 2 x 625ZZ rodamientos

- 1 x rodamiento 608ZZ

- 1 x M8 x 25 tornillo

- 1 x M5 tornillo o varilla roscada

- 2 x M3 40 ...mm tornillos

- 2 x springs

- 2 x M3 20 mm tornillos

- 4 x tuercas M3

- 4 x M4 tornillos

- 4x tuercas M4

Diseñador

spinorkitDescripción del modelo 3d

Reelaborado para dar 4:1 relación de transmisión con la boca tan cerca como sea posible a la parte inferior de x de la varilla y el centro de la mas...a lo más cerca posible a x varillas.Mi impresora es una Prusa i3 cuadro-marco. Sin embargo, las piezas impresas compré para hacer (mi primera impresora) incluido el x carro y Camina extrusora de aquí: http://www.thingiverse.com/thing:119616.

Yo estaba bastante contento con esta configuración hasta que me di cuenta de que la boquilla fue más de 0,1 mm más cerca de la cama cuando se encuentra en la x centro de la cama que estaba en el x bordes de la cama, haciendo el transporte subterráneo para más de 0.1 mm imposible. Finalmente, después de probar muchas cosas, he determinado que la causa de este problema fue el flex en la (8 mm) x varillas combinado con el centro de masa de la pesada Vadea el extrusor de estar bien delante de la x varillas y la boquilla también de estar bien delante de la x varillas.

Como resultado, decidí imprimir un nuevo extrusor y el monte que mover la boquilla tan cerca como sea posible a la parte inferior de x de la varilla y también mover el centro de masa más cerca de la x varillas.

Yo uso 3 mm de filamento y también me gusta usar un poquito de peso (250 g) paso a paso sobre la (no-Bowden) extrusora para mantener el x transporte total de la masa hacia abajo, por lo que necesito un razonablemente grandes, la relación de engranajes (1:4) y un Mk8 hobbed equipo suficiente par. Prusa compacto del extrusor de la prusa-vainilla repo me parecía simple y luz (M5 varilla y 625ZZ rodamientos) aparte de necesitar un gran paso a paso, así que me rediseñado para el uso de un 8 a 32 relación de transmisión (desde el 8 al 24). Para mover el centro de masa lo más cerca posible a la x varillas he planteado el motor, de manera que se podría extender a través de la parte superior de la x carro.

Yo no quería cambiar la x carro porque es muy suave, con no decantación, así que he diseñado un monte ( basado en http://www.thingiverse.com/thing:148536) para conectar mi E3D v6 directamente al carro tan alto como sea posible, y un offset para mantener el centro de masa cerca del centro de el carro en la dirección x. Entonces me tornillo de la extrusora a este monte el uso normal de 50 mm espaciados groovemount agujeros en la extrusora.

Tenga en cuenta que uno de los M4 tornillos utilizados para fijar la montura para el transporte también se utiliza para mantener el hot-end en el lugar.

Ahora puedo tranvía con precisión a través de toda la

200x200 placa de construcción.

Puedo imprimir estas piezas con Kisslicer medio de soporte (ABS).

El soporte está diseñado para ser un ajuste apretado en un E3Dv6 y es, probablemente, demasiado apretado para un E3Dv5, para que el extruder_cyl2_height parámetro debe ser reducida. La montura debe estar impreso con un 0,2 mm de altura de capa.

Yo uso una 0.26 altura de capa para el extrusor y la polea.

Cuando el montaje de la extrusora, no apriete las tuercas a cada lado de la frente-la mayoría de rodamiento contra el cojinete. Esto es debido a que el rodamiento de IDENTIFICACIÓN será un poco más grande que el diámetro del eje, por lo que las posibilidades son de que el rodamiento no se centra exactamente en el eje, causando que el eje se mueva a medida que gira. Es mejor dejar que el rodamiento delantero un poco floja, como la espalda, uno tiene que ser. Yo pack el eje donde el hobbed es un engranaje con un par de capas de papel de aluminio antes de montar el engranaje, hacia el centro.

Las fuentes también disponible aquí: https://github.com/spinorkit/Prusa3-vanilla

Parametros de impresión 3d

- 1 x MK8 hobbed engranaje- 2 x 625ZZ rodamientos

- 1 x rodamiento 608ZZ

- 1 x M8 x 25 tornillo

- 1 x M5 tornillo o varilla roscada

- 2 x M3 40 ...mm tornillos

- 2 x springs

- 2 x M3 20 mm tornillos

- 4 x tuercas M3

- 4 x M4 tornillos

- 4x tuercas M4